You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Snow plow cylinder diagram? Cushion Valve?

- Thread starter polemidis

- Start date

/ Snow plow cylinder diagram? Cushion Valve?

#21

Peter 315

Elite Member

Thats crazy over build, not??? I am thinking that I could even use plywood!!! I am not talking for the cutting blade at the bottom, but the blade that "transfers" or "pushes" the snow to the front and side

The mold- board?

Rustyiron

Super Member

yes. Its not a big expence. I am almost done with the design. I am working the fine details of cylinders mounts. Btw, is 10gauge good enough for the push plate? like 1/8" thickness?

Not so much the expense, but building the moldboard, tripp assy, and "A" frame......

and for the push plate, you mean the big plate on the ssqa? I'd do at least 1/4". Most of the plate is meaningless (in between the loaders ssqa mech. as long as you transfer any (pushing) load not bearing in that area to those points. On a plow a good heavy channel would do, but then you'll need a "high" point to lift from (chain) and that substantial rotational force will need to be dealt with. Better go 3/8":laughing:

Peter 315

Elite Member

yes. Its not a big expence. I am almost done with the design. I am working the fine details of cylinders mounts. Btw, is 10gauge good enough for the push plate? like 1/8" thickness?

push plates mount the plow to the frame or bucket of vehicle

Not so much the expense, but building the moldboard, tripp assy, and "A" frame......

and for the push plate, you mean the big plate on the ssqa? I'd do at least 1/4". Most of the plate is meaningless (in between the loaders ssqa mech. as long as you transfer any (pushing) load not bearing in that area to those points. On a plow a good heavy channel would do, but then you'll need a "high" point to lift from (chain) and that substantial rotational force will need to be dealt with. Better go 3/8":laughing:

I will make post at the BIY forum with the complete design later on, not to use the hydralics forum for that. But for the ssqa I will use 1/4" yes with lots of bracing. The rotational force comes to play now that I am extending the plow further away for the 12" cylinder. I will check it out though, thanks!!

LD1

Epic Contributor

Ok I hear you. No thrying to reinvent the wheel though, I had no idea about tha breather. I have already made the design to fit a 6" cylinder so to not extend too much in front of the tractor.

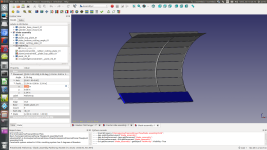

View attachment 535217

Arrgg, I have to change it again??

If you have already designed around a 2x6....might need a slight re-design....but......should be able to make it work.

If you are strictly talking about torque around a point....or energy potential.....the 2x6 should be similar to either a 1.5x1 or 1.5x12.

pi*r squared.....

For the 2" cylinder that is 3.14

For the 1.5 that is 1.77

Multiply that by the stroke and you get ~ 18.5 for the 2x6, 17.7 for the 1.5x10, and 21+ for the 12" version.

THAT's a good reference for the potential energy of the cylinder.

The rest is simply the geometry of the design....and how you design the lever moments.

One of the benefits of the longer and smaller cylinder though.....is you are applying the force further from the pivot.....meaning you have less plow beyond the cylinder. And dont have to be built as heavy to compensate for the unsupported part....if you follow what I mean.

I too question why you arent starting with a truck plow.

Dont know where you are located, but around here, you can buy a truck plow in pretty darn good shape for $300-$400....then all you need is to adapt it to a SSQA plate.

Building from scratch...you are gonna have what....

$100 for a cutting edge delivered

$150+ for a pair of cylinders delivered

$300 in steel

$50 is hoses and fittings

$100 in trip springs and misc hardward

Then....

Who is gonna roll (or worse us a press break in stages) for your mold board?

Who is gonna machine the pins and bushings for the pivots to allow tripping?

Couple of days in the shop welding....

Just not worth it IMO when truck plows are so plentiful.....at least in my area,

I bought a meyer 7.5' poly plow. half worn cutting edge.....good cylinders....$200.

Took the forks off my SSQA frame to attach the lower pins just like it hooks to the truck.....and added a receiver to the top to accept the chain so it will still float. Works perfect....and was cheap. And meyer plows are a dime a dozen and simple to work on. And parts everywhere

Exactly thatOne of the benefits of the longer and smaller cylinder though.....is you are applying the force further from the pivot.....meaning you have less plow beyond the cylinder. And dont have to be built as heavy to compensate for the unsupported part....if you follow what I mean.

About a used plow... Honestly I didn't thought I couldnt find such a cheap one. I will do my craiglist search. You guys may saved me a lot of time