SlowDog225

New member

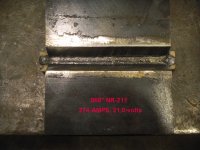

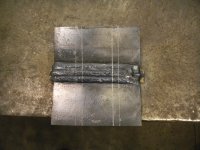

Don't everyone laugh at once but I was asked to weld some fence for a guy. At the time all I had was my portable wire feed welder available and big generator. As it turned out me using the flux core wire in it was fast and easier then stick. 10 lb of .035 Lincoln wire goes a long way. Am I wrong in considering this to use from now on?