Thank you all for reading & responding.

Oosik/Zebra - I tend to agree it feels like they just assembled them backwards.

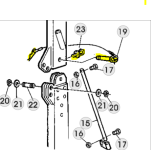

Phantom - I did try just pulling the pin and folding around the bolt the first time but it's physically not possible. Trying to pivot from the center of the bar like that means the bottom part of it would need to come down slightly and it impacts the top of the frame underneath. Pivoting from slightly in front where I have the pin works.

DiggingIt - Great advice on the hinge bolt tightness; I'll keep that in mind.

Chevy - Your setup seems to confirm it - I think that is how it should be. What is the purpose of the 3rd/lowest bolt on yours? Does the rops just sit on that so it doesn't come all the way down?

I'll try to contact the dealer and see what they say about it; not too confident in their knowledge (mostly a rural supplies store) but maybe they can pass it on to Kioti to check.

Cheers,

-M.

Oosik/Zebra - I tend to agree it feels like they just assembled them backwards.

Phantom - I did try just pulling the pin and folding around the bolt the first time but it's physically not possible. Trying to pivot from the center of the bar like that means the bottom part of it would need to come down slightly and it impacts the top of the frame underneath. Pivoting from slightly in front where I have the pin works.

DiggingIt - Great advice on the hinge bolt tightness; I'll keep that in mind.

Chevy - Your setup seems to confirm it - I think that is how it should be. What is the purpose of the 3rd/lowest bolt on yours? Does the rops just sit on that so it doesn't come all the way down?

I'll try to contact the dealer and see what they say about it; not too confident in their knowledge (mostly a rural supplies store) but maybe they can pass it on to Kioti to check.

Cheers,

-M.