Someone else has a Ford 1520 that had a problem with their Ford 1520 not driving after taking apart the HST.

The mechanic suggested that the spring may have been weak that pushes the rotating group against the swash plate. I think there is a possibility that this could be the problem. One way to check I suppose would be to add an extra washer next to the spring to see if the bypass pressure changes.

Their conversation is here:

After replacing the charge pumps seals, o-rings , gasket, - JustAnswer

Customer Question

Ask your own question now >

After replacing the charge pump's seals, o-rings , gasket, reassembly hyrostatic pump and installed new clutch plate on my son-in-laws Ford New Holland model 1520 tractor, the tractor moves only a slightdistance,1/2" to 1" when pedal is pushed for. or rev. Pump was flooded with oil,in neutral idled at start up. Oil level maintained at mark.Oil and filter changed 5 hr. before tear down. I ran trantor through maybe 50 cycles for. and rev. What would you suggest to do next?

Submitted: 85 days and 11 hours ago.

Category: Agriculture and Farm Equipment

Status: CLOSED

Bookmark and Share

Optional Information

Optional Information:

Make: Ford New holland

Model: 1520

Engine: 3 cyl diesel

What have you tried so far?: Worked pedal for. and rev.,low air pressure into dip stick hole, pushed into rear wheel with body weight. Tractor moved maybe 3 feet with approx. 50 cycles

Posted by Steve 85 days and 10 hours ago.

Expert's Answer

Hi my name isXXXXX may be able to help you out. I am familiar with hydrostatic drive tractors but I am not familiar with this particular model. can you tell what the reason for the original repair was?

85 days and 10 hours ago.

Customer Reply

Oil was leaking ,found to be a bad gasket

Posted by Steve 85 days and 10 hours ago.

Expert's Answer

two things that come to mind, you said that you replaced the clutch, does this disconnect the transmission so that the charge pump and hydrostatic pump stop turning and do you feel that it is installed correctly? and do you have anyway of checking the charge pressure?

84 days and 21 hours ago.

Customer Reply

Clutch does stop pump from turning. I feel clutch was installed correctly. I will have to buy a high gauge to test charge pressure-looseing test port plug - oil ran out- not spraying like under high pressure.Would you suggest to pressure test charge pump?

Posted by Steve 84 days and 20 hours ago.

Expert's Answer

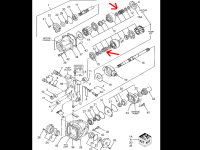

Yes I would suggest that you check the charge pump pressure next, I found a parts breakdown of the machine so I can see what you are dealing with, this unit appears to be what they call the HST, is his correct? I would imagine that the charge pressure should be around 100-200 psi and the hydrostatic pressure will run around 2500 psi. One other question, does the PTO work?

84 days and 20 hours ago.

Customer Reply

Yes , this is a HST.I will gauge the pressure and check to see if PTO is turning.I do not know if I will have enough time to buy gauge, 12 miles away and tractor is 20 miles from where I'll buy gauge to make test before church, if not I'll make test later and give finding about 10:00 central time Thanks

Posted by Steve 84 days and 19 hours ago.

Expert's Answer

Ok I'll wait to hear from you, did you rebuild the complete HST unit or did you just reseal the charge pump?

84 days and 13 hours ago.

Customer Reply

I only resealed charge pump. No pressure from charge pump.PTO shaft turns.I'm concidering spliting tractor apart again just to check things again.Any thoughts before I split it? Do you thank filter my have got plugged,air in any line,etc.I just remembered that I made a new gasket for between charge pump and transmission cast. Old gasket crushed was .018 ,new gasket was -I believe- .022.I may be wrong new gasket may been .016.I can see now if a thicker gasket was used there could be lost fluid- lost pressure I reassembled hydrostatic pump, it came partlly apart as I moved it on the bench.Sorry I missed so many details.Thanks

Posted by Steve 84 days and 11 hours ago.

Expert's Answer

I was going to suggest that you pull the relief valve cartridges out of the side of the case and see if one of them is stuck open, but after what you just told me I think that the machine may need to be split again, the parts breakdown looks like you may be able to take the top cover off of the transmission case and look inside while it's running and see if you may have a leak. I don't know if you can actually do it or not but I would try, it will probably be submerged in oil so drain most of it out so that there is just enough to run it. Let me know if I can help you any more. Thanks, XXXXX XXXXX

84 days and 2 hours ago.

Customer Reply

I do not recall a cover, but maybe there is.I'll get back to you , however it will be mid to late pm.Thanks

Posted by Steve 84 days and 1 hours ago.

Expert's Answer

Ok

80 days and 13 hours ago.

Customer Reply

I ORDERED A NEW GASKET TO REPLACE THE ONE I MADE. New Holland had a computer problem and orders are backed up 1 to 2 days. I will not get gasket till Tuesday or Wednesday. Tractor is apart waiting gasket.I took charge pump apart ,looks good.Will get back soon as I know more.Thanks and have a good week. I removed floor mat and metal plate,guess what I found- a cover plate. Ran tractor ,looked ok but failed to drain oil.OPPS If new gasket doesn't correct problem how far down should I drain oil, say just above lowest bearing? For how long , a minute?

Posted by Steve 80 days and 13 hours ago.

Expert's Answer

Drain the oil level as low as possible, just enough to cover the suction screen, and you should instantly see oil leaking, there should be very little oil leaking from anywhere in the HST unit,if there is then the charge pump will not be able to keep up with the leakage. you should also have low charge pressure. I don't know what the pressure is exactly but most systems are usually about 200 PSI charge pressure.

79 days and 11 hours ago.

Customer Reply

Thanks for the suggestions. If the new gasket comes in Tuesday I'll put the tractor together and recheck for leakage.Hope you don't live on the east coast.Last summer we could have used all -well most of the rain in central Ill. Thanks again Mark

Posted by Steve 79 days and 10 hours ago.

Expert's Answer

Nope, I'm in Utah, but I've helped a lot of people today that are trying to get their generators that have been in the barn for 3 years running, talk to you soon

77 days and 9 hours ago.

Customer Reply

Hi Steve. I received the new gasket yesterday, New gasket is .015 ,the one I made was .022. Put tractor together again , no leakage from pump,block ***'y or motor. This is a dry compartment , it will leak to the ground if it leaks.That is unless mices make a nest with bedding and hickory nuts plugging the drain hole letting oil build higher than clutch plate.I removed over a cup of material.The mices came through the HST rod hole.Still have the same problem,pump trys to move tractor but just no can do.NO pressure at high pressure relief valves. Let me know what you suggest now.Thanks,Mark

Posted by Steve 77 days and 9 hours ago.

Expert's Answer

Hello Mark, are you able to measure the charge pump pressure? this will be the oil that comes out of the small feed pump at the front of the HST. Also did you disassemble the rotating groups? these are the two units that have all of the small pistons inside of them. I am just shutting down for the night but I will reply to you at about 8:00 AM MST tomorrow. Steve.

76 days and 22 hours ago.

Customer Reply

Hi Steve.Would I measure charge pump pressure at filter located just below starter?(Drill and Tap banjo bolt for gauge) I reassemble the pump unit after it came apart as I was replacing O-rings ,seals and gasket first time .Has not been right since but everything looks good . I'm missing something.For now Mark

Posted by Steve 76 days and 22 hours ago.

Expert's Answer

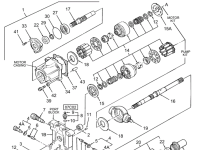

Hi Mark, sorry I couldn't get right back to you, I'm on the road today. Yes somewhere in that piping circuit would be a good place to check the charge pressure, I'll bet there is a port to check it though. In the parts information that I have it looks like there is a tube and fitting that goes to the top of the transmission case, I though that may be the charge pressure test port. Before you go through the trouble of tapping into the system, just loosen the filter and crank or start the engine and shut it back off and see if there is pump flow at that location. I have another question about the rotating groups. Where the circular grooves are on the brass and steel sealing surfaces, were the surfaces in good condition and when they assembled back together there should have been heavy spring pressure required to force those two surfaces together, does this sound familiar?

76 days and 14 hours ago.

Customer Reply

Hi steve. I drilled and tapped the banjo bolt for a gauge I have 80 psi. at 2000 rpms.When I move foot pedal pressure drops off.The mating surfaces of plate pump and block look good.There is a spring kept in place by a snap ring.Chances are I took pump apart looking for 1 of 3 small pins that dissappeared when pump ***'y slide from housing. Maybe the ring snapped out. Later I found the pin on the floor. NO, I did not feel any spring pressure.I guess I know what I'll be doing tomorrow.Have a good evening.Mark

Posted by Steve 76 days and 13 hours ago.

Expert's Answer

Hi Mark, it sounds like were on to something, it's difficult to explain but what I mean, but just realize that there has to be spring force holding the two rotating faces together, there will be about 1/4 to 3/8 of an inch of crush. When the faces are not held tightly together they are forced apart as the oil pressure increases and they can't build high pressure and the charge pressure drops because it can't keep up with the leakage. the charge pump pressure should drop very little from no load to load, this is the number one way that we evaluate the condition of hydrostatic drive systems. The input and output ends should be difficult to impossible to turn by hand when they are assembled properly, if it take a small pipe wrench or a pair of channel lock pliers to turn it, that is normal. let me know, Steve

76 days and 12 hours ago.

Customer Reply

Steve.Yes this makes sense, no pressure to keep mating surfaces together would cause internal leakage. The input shaft is easy to turn by hand. Thanks Steve I'll keep you posted.

Posted by Steve 76 days and 11 hours ago.

Expert's Answer

OK

75 days and 11 hours ago.

Customer Reply

Hi Steve.Took tractor apart again. Removed HST unit. I did not see anything

out of place, nothing added or missing.However on a parts breakdown dealer

gave me it shows a keeper -collar-spacer-whatever-holding the three small

pins between HST rotating cylinder block and retainer( part that rides next

to retainer plate). the service manual I have does not show any keeper, pin

just set in pockets of the cylinder block. Tomorrow I will check spring

***'y to make sure it is right.I agree with you that there must be a way

of holding oil inside of pump case.I do not see how this happens.To me it

looks like the spring is pushing the plates apart.I'm going to sign off for

now, may things will look better tomorrow.Keep up the good work STEVE I'll

be in touch. PS I'm planning to go to dealer tomorrow to ask about the

three pin keeper.

Posted by Steve 75 days and 10 hours ago.

Expert's Answer

If the three pin keeper is what I'm thinking about, then that is what puts tension on the port plate. Let me know what you find

73 days and 12 hours ago.

Customer Reply

HI STEVE Took HST unit to Ford Dealer. Shop mechanic said pump looked good.Three Pins do not need a keeper-bad parts drawing.I split tractor at rear and center casing. Removed the rest of HST unit . I dissassembled unit,cyl,pistons,spring,plates,valves,everything looks goods.Took HYD. and TRANSMISSION filters off, cut them open with filter cutter, no built up at all,took shop vac.blow into cooling lines -open,blow into transmission case,no restraiction,filter casting clean(transmission case).I believe I will reassemble unit and have it tested.The suction filter fluid level was one and one half inch low-case level was higher.Seems that relief valve assy. was harder to remove,but this would cause higher pressure, right? Your Thoughts Steve Thanks Mark

Posted by Steve 73 days and 12 hours ago.

Expert's Answer

Hi Mark, there are probably two high pressure relief valves, one for forward and for reverse. the fact that you have 80 PSI charge pressure in neutral and then it drops when you actuate it is what we need to focus on. Can you tell me how the swashplate actuates? is it just a mechanical linkage or is there a hydraulic cylinder that moves the swashplate? Also, do you think that you can assemble and test the HST before you put it back into the tractor?

Posted by Steve 73 days and 11 hours ago.

Expert's Answer

Mark, I just looked at the parts breakdown again, I assume that you are assembling this with the shaft in the vertical position, when you do this, it looks like you hold the port block in position and put the rotating group together on top of and then bolt the housing on to the port block, when you do this you should have to pull the housing to the port block with the bolts about 3/8 of an inch, this is the spring tension that I was talking about, then I assume that you flip the unit over and install the other rotating group and housing the same way. Is that the way it goes together? If it is, then the problem almost has to be in the valve cartridges in the port block. Also I can see that there is a forward/reverse pedal that is directly connected to the pump swashplate.

Steve41218.1793301968

72 days and 10 hours ago.

Customer Reply

Hi Steve. Yes, this is correct. I see now how the three small pins press against the spring,pressing the valve plate and port block together.I'm 99%sure HST is ok to reinstall, but would like to have it tested. If no luck tomorrow I may put it back in.By for now, be sure to vote. Mark

Posted by Steve 72 days and 10 hours ago.

Expert's Answer

Hi Mark, I already voted, good luck let me know what happens. Steve

69 days and 11 hours ago.

Customer Reply

HI STEVE. A very dissapointing day. I finished putting HST. in tractor . Results same.Charge pump is putting flow to create 80#psi.Pump is pumping some flow as seen as oil coming out of high pressure relief valve test ports but no pressure.What would you suggest I do next? Saturday a x -- ford repair is coming to help.Steve I'm going to have you paid because you have been helpfull, I would like to keep you on board till tractor is running properly.Your though. SO LONG FOR NOW. Mark

Posted by Steve 69 days and 11 hours ago.

Expert's Answer

Hi Mark, that sucks. I'm just about out of ideas, but I do have one more. Is there only one high pressure relief valve or are there two? If there is only one then there has to be some sort of double check valve so that only the high pressure from either forward or reverse gets to the valve, If the check valve is stuck open then the pressure can leak from the forward to the reverse side or vice-versa. Please keep me in the loop, I'm curious what you find. One of my hardest learning experiences was on an International Skip Loader with a hydrostatic drive and I spent 80 hours troubleshooting it, and the answer finally came to me in a dream that woke me up. and I went back to the machine and had it fixed in two hours. So start dreaming. Talk to you soon, Steve

69 days and 9 hours ago.

Customer Reply

HI STEVE Thanks for wanting to stay on board.Unit has only one high pressure relief valve. There are 2 check valves which I had out, inspected,looked good,and no binding , so I reinstalled them.I just don't get it, I removed charge pump and HST pump,replaced oil seals , o-rings and gasket and now tractor won't run.Question,if a oil seal or o-ring is leaking air-not enough to make a squeal-could this be the cause or would there have to be a larger amount? I worked at CAT EAST PEORIA,ILL.as a millwright ,worked on some hyd. pumps not too many,they would be pumping oil -seals leaking and the noise would drive you away. Note-Back then pipefitters would do all the trouble shooting , replace valves , accumalators ,etc. we would replace/replace the pumps.Had some hyd. training but never good to practice it.SO long for now Mark

Accepted Answer

Mark, I assume that the charge pressure is still dropping when you try to activate forward or reverse, if that is the case then the most likely cause is the spring pressure holding the rotating groups against the port plates, it will build charge pressure until the main pressure starts to increase and then it can't hold back the extra pressure so it leaks and drops the charge pressure.

Read more: After replacing the charge pumps seals, o-rings , gasket, - JustAnswer

After replacing the charge pumps seals, o-rings , gasket, - JustAnswer