KentT

Elite Member

- Joined

- Mar 31, 2005

- Messages

- 2,838

- Location

- Sevierville, TN

- Tractor

- 1993 Power Trac 1430 w/Kubota diesel engine

I think you're correct with the 14cc size assumption on the tram pump. I agree that theoretically, it could pump 13.31 GPM, requiring 23.29HP. However, that 25HP engine (at 3600 RPM) is also spinning the pump for the lift arms/tilt/steering circuit at all times, in addition to the PTO pump. Even if there is no added load on either of those hydraulic circuits (not steering, lift arms at rest, and the PTO not engaged -- those pumps are still pumping oil, even if that oil is simply returning to the tank. So, I don't think you EVER have 23.29HP going to the tram pump. How much less depends on how the other two circuits are being used....

Now, let's look at how pressure/flow relates to the tram circuits themselves. There are TWO circuits, with TWO motors in each one. So, that volume is split in half, with half available to each circuit. Pressure is the same across both circuits, but the front wheelmotor will "consume" half that pressure while the rear wheelmotor will "consume" the other half. In a "no added load" situation, with the PT up on jackstands and only turning the wheels, you could likely get somewhere around 12GPM, perhaps a bit more, flowing through the tram circuits (why I suggested disregarding anything above 12 GPM in my first post) with the remainder of the engine power going to the other two pumps.

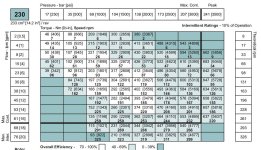

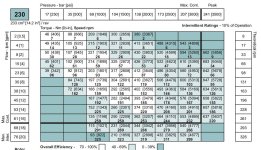

At 12GPM, according to the specs, a 230 wheel motor would turns 192 RPM, at 1000 PSI. But, that doesn't happen -- half the flow (6 GPM) is going to one wheel motor circuit, half (6 GPM) to the other. According to the chart, at 6 GPM the wheelmotors would turn 96 RPM at either 250 or 500 PSI pressure. It likely would take somewhere close to 500 PSI to get the PT moving if not on jackstands (automatic hydraulic brakes often require about 400 PSI to release, as an a example, and allow the motors to start turning). So, at 12GPM from the pump (6 GPM to each wheel motor) you'd be turning 96 RPM -- or about 6.3 MPH with 23" tall tires, according to my conversions.

You may actually be able to get more than 12GPM flowing the tram pump, closer to 14 (the next table value) in no-load/no-added-load conditions, before you run out of engine HP, but since the table does not show 7 GPM (half of 14), it is hard to make any higher conversion or calculations...

Bottom line -- I think your interpretations are pretty solid -- but you haven't considered that the GPM must be evenly split across the two tram circuits... and there's no need to add any "fudge factor adjustments"... I think the numbers are pretty accurate, just a bit difficult to interpret.

Now, let's look at how pressure/flow relates to the tram circuits themselves. There are TWO circuits, with TWO motors in each one. So, that volume is split in half, with half available to each circuit. Pressure is the same across both circuits, but the front wheelmotor will "consume" half that pressure while the rear wheelmotor will "consume" the other half. In a "no added load" situation, with the PT up on jackstands and only turning the wheels, you could likely get somewhere around 12GPM, perhaps a bit more, flowing through the tram circuits (why I suggested disregarding anything above 12 GPM in my first post) with the remainder of the engine power going to the other two pumps.

At 12GPM, according to the specs, a 230 wheel motor would turns 192 RPM, at 1000 PSI. But, that doesn't happen -- half the flow (6 GPM) is going to one wheel motor circuit, half (6 GPM) to the other. According to the chart, at 6 GPM the wheelmotors would turn 96 RPM at either 250 or 500 PSI pressure. It likely would take somewhere close to 500 PSI to get the PT moving if not on jackstands (automatic hydraulic brakes often require about 400 PSI to release, as an a example, and allow the motors to start turning). So, at 12GPM from the pump (6 GPM to each wheel motor) you'd be turning 96 RPM -- or about 6.3 MPH with 23" tall tires, according to my conversions.

You may actually be able to get more than 12GPM flowing the tram pump, closer to 14 (the next table value) in no-load/no-added-load conditions, before you run out of engine HP, but since the table does not show 7 GPM (half of 14), it is hard to make any higher conversion or calculations...

Bottom line -- I think your interpretations are pretty solid -- but you haven't considered that the GPM must be evenly split across the two tram circuits... and there's no need to add any "fudge factor adjustments"... I think the numbers are pretty accurate, just a bit difficult to interpret.