ZLineFabrication

Member

I run a small landscaping business and have been building a shop for several years. I have gotten bored with the mow and blow, fert and squirt anyone who gets laid off is in the business atmosphere. I miss being creative. I would like to start a repair business because I have skills and have a creative streak. I guess I am reluctant to pull the trigger due to perceived tool deficiencies. I would like to know from the guys that run shops what else I would have to have just to open the side door. Here is a list of the main Items I have collected.

Hobart 210 Mig

Miller 180 sd tig/stick

Miller spectrum 875 Plasma cutter

Jancy mag drill

Cheap drill press

40 ton press and brake

Ellis belt sander

Horizontal liq cooled band saw

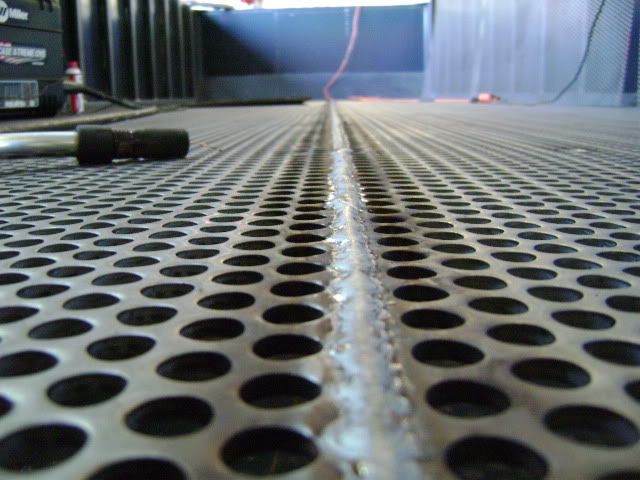

small weld table 2.5X4'

sand blaster Kit

9" hand grinder several 4.5 grinders.

2 ton cherry picker

good air compressor

So I know I will need a torch set but will probably wait till I have to get one. So what else would I have to have? Be assured if my funds were unlimited I would not need to ask this question. I would just go by it all. But my business style is to start out with what you have to have and add the rest as you grow. So what do I need to start? Thank you in advance.

its extremely hard starting out. first and most important would be to brush up on your business skills. by this i mean "people skills". get your name out there and build a reputation. remember not to get big headed. it only takes one bad experiance to ruin it all. the markets arent the same as they were 5 years ago...or even 2 years ago. you might be able to charge $50-$65 p/hr for a repair, but dont expect to be able to bill for total hrs on every job. "fair" market value is key.

ZLineFab