I'm working on my welding table (4' by 6' by 1/2" thick). It is currently sitting on two 50 gal drums. I will add some legs soon and I was wondering if there are some standard slot sizes for these like how milling machine t-slot tables are built? I had thought about leaving half of it solid and putting 8 slots in the other half like wheel spokes for clamping. I have a stick welder so the leads are always hot. Any ideas for electrode wand holders? I was thinking some kind of wooden box or something on each side of the table. Don't want to flash myself!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

welding table slots

- Thread starter swick1

- Start date

/ welding table slots

#1

jake98

Veteran Member

- Joined

- Nov 10, 2007

- Messages

- 1,881

- Location

- Dingmans Ferry PA

- Tractor

- 53 Cub, 70's JD 410, Kioti 25hst

Maybe get one of these clamping sets first, then make the slots to fit, they're available in 3/8" and 1/2" from what I've seen.

G1076 52 pc. Clamping Kit - 1/2" Bolt Size

G1076 52 pc. Clamping Kit - 1/2" Bolt Size

Thanks for the suggestion, but I was hoping for something a little faster than machining clamps. Are there any welding specific clamp systems out there? I may just make bigger slots and put my c-clamps through them.

LD1

Epic Contributor

Cant really help with the slot suggestion, but I can make a few other...

First, if you do slot it as I am imagining, be carefull not to go overboard and weaken the table.

Another suggestion is to maybe incorporate an area for cutting. The neatest one I see, and was simple, was just a hole in the table maybe 2' x 2' and it just had bar-grate in there. That way, you could lay the peice flat and cut and not have to worry about burning through the table. And it gave all the slag a place to fall away. If I ever make another welding table, I think the WHOLE top will be heavy bar grate. and the openings in bar grate are usually large enough to drop a c-clamp in:thumbsup:

Another suggestion (an we have this in our shop at work) and it may be a lot more work than you want, but we have a metal post mounted on the wall for hooking the ground clamps to. And then a heavy guage cable laid in a trench in the concrete and attached to the leg of the table. One less cord to worry about running over and getting tangled.:thumbsup:

And I cant really help much with the electrode holder But I wouldnt want to use wood on a welding bench. They might not last very long:laughing:

But I wouldnt want to use wood on a welding bench. They might not last very long:laughing:

First, if you do slot it as I am imagining, be carefull not to go overboard and weaken the table.

Another suggestion is to maybe incorporate an area for cutting. The neatest one I see, and was simple, was just a hole in the table maybe 2' x 2' and it just had bar-grate in there. That way, you could lay the peice flat and cut and not have to worry about burning through the table. And it gave all the slag a place to fall away. If I ever make another welding table, I think the WHOLE top will be heavy bar grate. and the openings in bar grate are usually large enough to drop a c-clamp in:thumbsup:

Another suggestion (an we have this in our shop at work) and it may be a lot more work than you want, but we have a metal post mounted on the wall for hooking the ground clamps to. And then a heavy guage cable laid in a trench in the concrete and attached to the leg of the table. One less cord to worry about running over and getting tangled.:thumbsup:

And I cant really help much with the electrode holder

Scooby074

Super Member

Thanks for the suggestion, but I was hoping for something a little faster than machining clamps. Are there any welding specific clamp systems out there? I may just make bigger slots and put my c-clamps through them.

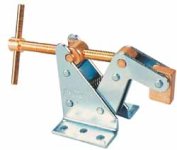

THere are several welding quick clamps available at different price points and mounting style. These are but a few examples.

ericher69

Veteran Member

Just another clamp available

http://www.millerwelds.com/products/workstations/arcstation/

Sent from my sweet iPhone4 32Gb

http://www.millerwelds.com/products/workstations/arcstation/

Sent from my sweet iPhone4 32Gb

kansas john deere

Bronze Member

- Joined

- May 26, 2011

- Messages

- 81

- Tractor

- 1986 john deere 318

Just my opinion so take it with a grain of salt. Your table is about the right size except for one thing 1/2in. thick is way to thin in my opinion. The one I had at my old place was 3in. thick. Now that might be overkill but you didnt just pick it up to move it.........LOL. With it being only 1/2 in. I believe you will get a lot of spring action in the top when you cut your slots for clamping things to the table. Now as far as a cutting table I would make one seperate from the welding table. A really nice design is make one out of angle iron for the edge and then put in some flat iron inbetween vertical. Like I said take it with a grain of salt but that is what I would do..,...KJD

I like the idea of a fab table and a cutting table made out of grate material. I am going to brace my slotted table with c or angle extrusions. It shouldn't warp too much. I like those clamps. I'll have to get some when I get some spare cash. I keep spending it on welding projects and I just weld everything on top of 6x6 blocks and shims

IslandTractor

Super Star Member

- Joined

- Sep 15, 2005

- Messages

- 17,101

- Location

- Prudence Island, RI

- Tractor

- 2007 Kioti DK40se HST, Woods BH

Check out Strong Hand (?Stronghand) clamps which are specifically designed for welding. Very nice.

k0ua

Epic Contributor

Check out Strong Hand (?Stronghand) clamps which are specifically designed for welding. Very nice.

yeah that whole stronghand table and clamps system is way cool, but too much $ for me. Now if I was trying to make a living welding.. maybe a different story.

James K0UA