lhfarm

Veteran Member

I'm using hydraulic fluid marked 20W. Instructions called for 10W oil. I may try to change to oil after I test the flow direction.Are you using oil or hydraulic fluid? Some pumps are designed to use motor oil.

Thanks,

I'm using hydraulic fluid marked 20W. Instructions called for 10W oil. I may try to change to oil after I test the flow direction.Are you using oil or hydraulic fluid? Some pumps are designed to use motor oil.

Over the weekend was able to drain the tank and disconnect the hoses to test the flow direction. It is correct. However, when draining the tank, there was only a couple of quarts of fluid. I had added the 5 quarts per instructions when I started testing. Assuming another quart remained in the hose, pump and ram, I was running a couple of quarts low. There is no way to see, test the fluid level and I hadn't realized that I had lost that much fluid through leaks.

When I reconnected the hoses and added 4 quarts of fluid, the lift worked. It would raise 3 large adults (~ 600 pounds) standing on the draw bar. The pressure gauge still only read about 400 PSI, so the pump may be worn, but it will certainly lift any plow I'd hang on the back.

I will accept the idiot of the month award for not checking the fluid level earlier. Thanks for all your time and suggestions.

....

If you had a leak that bad, you would surely know it.

Do you have a filler cap that you can remove and look in the tank?

I hope you used motor oil this time, like the instructions call for on page 3. The Gerotor pump it uses will not develop full pressure with hydraulic oil. You can use 20W, since you are not farming with it in the winter.

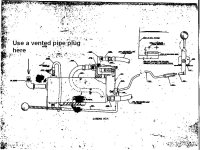

You need a vented pipe plug on the fill tube, as marked here:

View attachment 319861

Good luck at the shows! :thumbsup:

I had several leaks so it was possible. The filler pipe extends from the tank and has a 90 degree elbow. So you can't see into the tank or otherwise tell the level of the fluid. I am assuming I can fill up to the level of the filler pipe, but no more.

Right, I think you should see oil in the elbow

I didn't use motor oil, but will give it a try, just to see if it makes a difference. I'll have to design a vented pipe plug. I used a small extension pipe when I cycled the pump several times, but put the solid plug back as shown.

The shows aren't competitions, just displays. But I do want the lift to be as original as possible.

Thanks,