Your 2 cents are always welcome here! I've never had the loader off the tractor and most of the time had left the hoe on. I'm guessing the hoe complete adds close to 800 pounds, but sticks out further than a weight box would and may have a greater influence. What's your thoughts on loading tires? I don't seem to be able to make that decision. Is your property sloped?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XJ2025 Liquid ballast.

- Thread starter jdom84

- Start date

/ XJ2025 Liquid ballast.

#31

mslisaj

Gold Member

- Joined

- Nov 3, 2017

- Messages

- 323

- Location

- Klamath Falls, Oregon

- Tractor

- LS MT125 Loader/Backhoe John Deere Sabre Lawn tractor w/Snow Blade

Well my property is very level but I did have an occasion to go in my neighbors yard and I had to run along by his house where there was a drop off of about 2" or so. I was going slow but this "tip" was not a comfortable feeling. Also the backhoe is an extremely heavy add on component and it's top heavy in it's own right so I realize if I have any momentum the weigh of the hoe alone could take me over.

Now just my thoughts on loaded tires and this is only for me. The little tires on my machine are about all I can handle alone in their original configuration. I use guide bolt/pins to get the wheels on and off as there are no studs on my axle flanges only a small raised hub. I have at one time worked in a tire shop in my long career and I had to deal with a pair of loaded front tires off a Cat back hoe and the concentrated weight of that was unbelievable and I could not handle them alone. I think they had the weighted foam fill in them but it just kind of flipped a switch in my mind about that idea. Then I have seen my share of rusted rims from the liquid salt fill. Don't get me wrong, loaded (weighted) tires have their uses and make a lot of sense but not on my machine and the way I use it. Besides I have a little gyro in my head that if it goes off center just a little I slow and stop immediately. I've watched real equipment operators that would take machines way beyond where I would go and not damage anything but I don't want to damage my machine first or get hurt of killed on it either. So a lot of respect goes into my operating style.

A good point that you made about the center of gravity with the backhoe on is truly quite a distance behind the center of the rear axle. So it's weight also has the advantage of that "arm" making it longer and levered against the front end. So the bottom line for me is to take the hoe off to do my snow work so I have more weight on the front tires and can steer and actually used the 4WD and then add a weight to the three point hitch that loades the rear axle and also has a low center of gravity. And like operating a forklift, keep the loader as low as you can for traveling and line up with your delivery point, get there and raise the load slowly and dump it.

Just my just my thoughts here and as usual you ask a simple question and I have to run off into a big explaination but here you go.

Happy tractoring,

Lisa

Now just my thoughts on loaded tires and this is only for me. The little tires on my machine are about all I can handle alone in their original configuration. I use guide bolt/pins to get the wheels on and off as there are no studs on my axle flanges only a small raised hub. I have at one time worked in a tire shop in my long career and I had to deal with a pair of loaded front tires off a Cat back hoe and the concentrated weight of that was unbelievable and I could not handle them alone. I think they had the weighted foam fill in them but it just kind of flipped a switch in my mind about that idea. Then I have seen my share of rusted rims from the liquid salt fill. Don't get me wrong, loaded (weighted) tires have their uses and make a lot of sense but not on my machine and the way I use it. Besides I have a little gyro in my head that if it goes off center just a little I slow and stop immediately. I've watched real equipment operators that would take machines way beyond where I would go and not damage anything but I don't want to damage my machine first or get hurt of killed on it either. So a lot of respect goes into my operating style.

A good point that you made about the center of gravity with the backhoe on is truly quite a distance behind the center of the rear axle. So it's weight also has the advantage of that "arm" making it longer and levered against the front end. So the bottom line for me is to take the hoe off to do my snow work so I have more weight on the front tires and can steer and actually used the 4WD and then add a weight to the three point hitch that loades the rear axle and also has a low center of gravity. And like operating a forklift, keep the loader as low as you can for traveling and line up with your delivery point, get there and raise the load slowly and dump it.

Just my just my thoughts here and as usual you ask a simple question and I have to run off into a big explaination but here you go.

Happy tractoring,

Lisa

jdom84

Gold Member

If you are already wanting to build a ballast box/tool carrier, I think the size you are thinking would be good. The backhoe sits out further then a ballast box would so the tractor holds the weight different.

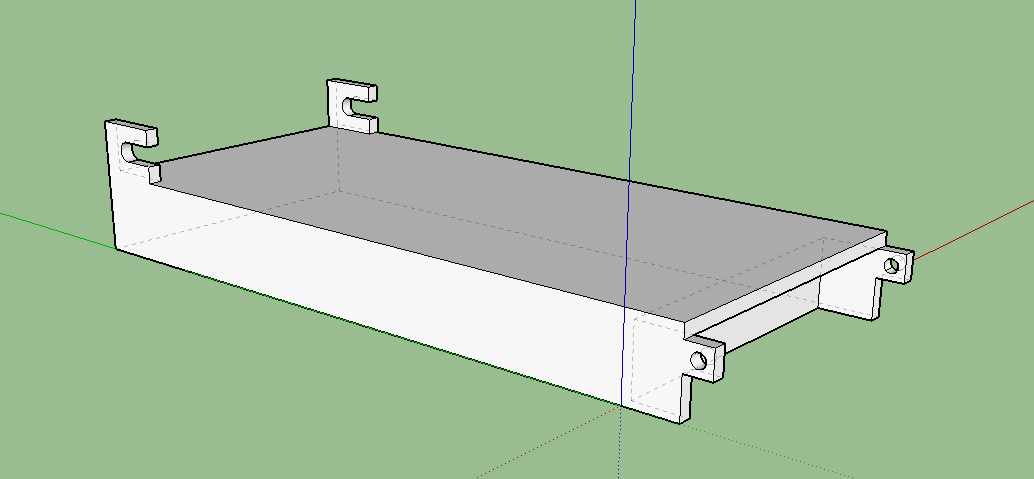

This summer I'm going to be using a box blade to level out quite a bit of my "inside" yard and once the box blade is on the ground... there wont be the extra weight on the tractor. And after using the tractor with the loaded tires now for a couple weeks, I can definitely feel the difference with just the 400lbs in the wheels. But I think I might need a bit more when dragging/scrapping the dirt with the box blade, wheel weights would be a nice addition but I haven't seen them for our size tractors... so I might build a weight that connect to the BH connections. I wont know if it will be needed until I start moving the dirt this spring. The issue would be hooking it up and taking it off, would need some sort of jack built in.

This is just a mock-up, I didn't measure anything.

This summer I'm going to be using a box blade to level out quite a bit of my "inside" yard and once the box blade is on the ground... there wont be the extra weight on the tractor. And after using the tractor with the loaded tires now for a couple weeks, I can definitely feel the difference with just the 400lbs in the wheels. But I think I might need a bit more when dragging/scrapping the dirt with the box blade, wheel weights would be a nice addition but I haven't seen them for our size tractors... so I might build a weight that connect to the BH connections. I wont know if it will be needed until I start moving the dirt this spring. The issue would be hooking it up and taking it off, would need some sort of jack built in.

This is just a mock-up, I didn't measure anything.

You had hinted at the idea earlier. I think it could be a good one. For me, not so much as I will want the ground clearance in the flats. I may even switch the crossbar out below the back of the loader. I have a rear blade rather than a box blade. That in itself doesn't interfere with traction in gravel. That may be a project also to frame up some scarifier teeth to help with the crown. The misses wants to cut the ditch in on the side of the drive. I'm thinking that part will work as is, but if not it could become an offset blade! Now someone in a current thread made a midmount blade on their GC?. That could be a good answer for our blading needs. Get on that jdom!

jdom84

Gold Member

I tried making a ditch with my back blade once. The ground here is to hard... thats how I ended up with a box blade

The mid mount grader idea is a good one, Ill have to look into it!. Out at the mine we have some 1/2 thick steel sections cut out of a 3 foot diameter pipe that was made into a trommel.

The mid mount grader idea is a good one, Ill have to look into it!. Out at the mine we have some 1/2 thick steel sections cut out of a 3 foot diameter pipe that was made into a trommel.

CMV

Platinum Member

Would it be possible to make a small plate with a vertical piece of round bar stock to go into the draw bar mount? That could hold some stacked plate weights. Seems like that would be close in enough there would still be clearance for a box blade. Could be a way to have easily added/removed weight low on rear axle?

Can't really draw well, but something like this:

Can't really draw well, but something like this: