Jmlcolorado

Bronze Member

- Joined

- Apr 4, 2020

- Messages

- 69

- Tractor

- Yanmar ym240

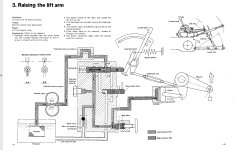

I was spreading some dirt this evening for a neighbor using a blade.

Worked great. When I was done I stopped and raised the 3 point all the way up to travel home.

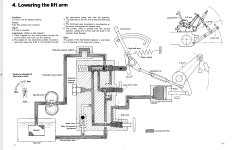

Now it won稚 drop.

It痴 stuck solid in the raised position.

I checked the lockout knob under the seat and rotated it both directions with no change.

Also checked the drop speed lever. No change in either direction. This was with engine running.

Machine has been off now for a couple hours and it痴 still locked up solid.

Anyone run into this?

Worked great. When I was done I stopped and raised the 3 point all the way up to travel home.

Now it won稚 drop.

It痴 stuck solid in the raised position.

I checked the lockout knob under the seat and rotated it both directions with no change.

Also checked the drop speed lever. No change in either direction. This was with engine running.

Machine has been off now for a couple hours and it痴 still locked up solid.

Anyone run into this?