iointerrupt

Member

- Joined

- Sep 12, 2011

- Messages

- 46

So I recently built a backhoe/excavator ripper/trencher for my Kubota KX-41, herein referred to as Giant Metal Claw. Much of the design came from threads here, so I figured I'd document it a bit for others to build from too.

First off, much thanks to IslandTractor for his thread, and bluehog for his thread thread, documenting their rippers.

Both of these are variants of the Michigan Iron and Equipment ripper</a>. As well, I also based my design off of the smaller Bro-Tek ripper. If you don't want to build one, buy one of the above.

Design

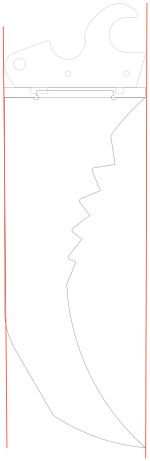

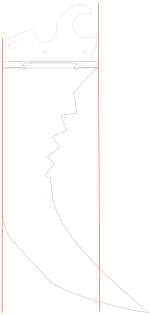

Attached below is a SolidWorks file of the whole, as well as DXF files of each piece. Use either as is, or to just get dimensions from. Naturally if you want to use it, you'll have to redesign the mounting hook plate, as the ones in the files are for a KX-41 quick attach.

I was more interested in a small trencher than a root ripper, and the design shows that. The main shank of Giant Metal Claw is like the MIE ripper, with some progressive teeth and side gussets. But the additional back plates for trenching are like the Bro-Tek ripper. Unlike the Bro-Tek ripper though, I added some little triangle gussets behind the back plates, which made me feel a lot more confident in them holding up.

Total length of the shank is 20". If I had to do it again, I'd probably go for the full 24". The KX41 is a small excavator, and seems to have no trouble with it. If you had a bigger machine, I'd consider going much larger.

Also I'd either make the gussets bigger, or skip them entirely. The ones I designed on here seem too small, but at the same time, in practice digging with it, seem to do just fine anyway.

Fab

Everyone always wonders about thicknesses, so here they are:

Total weight is somewhere around 40lbs accordingly to SolidWorks, feels about it. Light enough that hooking it up is easy enough, can balance it with one hand and slide the retaining pin in with the other.

All the pieces of Giant Metal Claw were CNC plasma, then welded them with a Millermatic 252. I tried to put tabs on everything to make it all snap together and simplify fixturing a bit. Given the material size, I kicked the welder all the way up into spray-transfer range. This was my first time doing much spray-transfer, so don't look too closely at the welds, as there is a lot of bad undercut. Even so, everything has held together fine even in rough use.

After welding, I did some test trenching with it, then sandblasted it, primed it, and gave Giant Meta Claw a spray paint design stolen entirely from bluehog. I briefly considered sending it out to get powder coated, but couldn't see it being worth it, given it's all going to get scrapped off almost instantly.

Use

So in practice, Giant Metal Claw has worked perhaps even better than I expected. I've got extremely hard clay soil full of large rocks, and it cuts through it like it isn't even there. The basic trenching operation with it is to plunge it into the soil, then curl it around such that the tip points back to the machine, and the backplates are parallel to the ground. Then raising it all up will cause the backplates to scoop the dirt out of the trench.

Gives a trench maybe 5" wide, which I actually often find is a little bigger than I want. With not much more digging, can easily expand the trench to 10" with it. I put 5/8-11 tapped holes on the backplates for the possibility of adding trencher wings like Bro-Tek sells, but I suspect I never will bother. If you need a bigger trench, just go right to a 9" bucket instead.

I haven't done much root ripping with it yet, although it's eaten through everything I've run into while trenching without the machine even noticing it. However, if you need to pop 2"+ roots, I'd suspect you'd want something a bit more aggressive for the teeth. The lack of the beveled edge leads you to just using pure hydraulic force to pop them, and on my little machine, this only goes so far.

On the other hand, it works amazingly well at popping rocks and boulders out of the ground. I probably won't use anything else now when dealing with rocks. I used it to hook a 1000lb boulder and move it from one side of a trail to the other with no drama.

Wear

Which leads us to the topic of wear, since a lot of thinking seems to go into that. Giant Metal Claw is just made out of standard A36, and I did nothing to attempt to harden any of it. Above is a picture of the (sandblasted clean) tooth after about 2 hours of trenching. As you can see, the side edges are indeed starting to roll over.

After about another 5 hours of trenching, the tip lost all it's original sharpness, and even took a dent or two in it. And by the the paint wear, you can see the lower end unsurprisingly takes the majority of the abuse.

But even so, I don't think I'll ever wear it enough to impact performance. By time it wears down enough to be an issue, I think I'll be time ahead to just weld-build it back up and grind it back to shape. Compared to trying to work out a design with a hardened tip, this seems just fine.

Closing

Overall, I think I'm probably going to be using the my 9" bucket a lot less, and Giant Metal Claw a lot more. If you have any questions about it, feel free to ask.

Now I just have to finish Giant Metal Thumb...

First off, much thanks to IslandTractor for his thread, and bluehog for his thread thread, documenting their rippers.

Both of these are variants of the Michigan Iron and Equipment ripper</a>. As well, I also based my design off of the smaller Bro-Tek ripper. If you don't want to build one, buy one of the above.

Design

Attached below is a SolidWorks file of the whole, as well as DXF files of each piece. Use either as is, or to just get dimensions from. Naturally if you want to use it, you'll have to redesign the mounting hook plate, as the ones in the files are for a KX-41 quick attach.

I was more interested in a small trencher than a root ripper, and the design shows that. The main shank of Giant Metal Claw is like the MIE ripper, with some progressive teeth and side gussets. But the additional back plates for trenching are like the Bro-Tek ripper. Unlike the Bro-Tek ripper though, I added some little triangle gussets behind the back plates, which made me feel a lot more confident in them holding up.

Total length of the shank is 20". If I had to do it again, I'd probably go for the full 24". The KX41 is a small excavator, and seems to have no trouble with it. If you had a bigger machine, I'd consider going much larger.

Also I'd either make the gussets bigger, or skip them entirely. The ones I designed on here seem too small, but at the same time, in practice digging with it, seem to do just fine anyway.

Fab

Everyone always wonders about thicknesses, so here they are:

- Shank: 1/2"

- Upper plate and mounting ears: 1/2"

- Gussets: 3/8"

- Back plates: 3/8"

- Tooth tip: 3/8" + 1/2" + 3/8" == 1.25"

Total weight is somewhere around 40lbs accordingly to SolidWorks, feels about it. Light enough that hooking it up is easy enough, can balance it with one hand and slide the retaining pin in with the other.

All the pieces of Giant Metal Claw were CNC plasma, then welded them with a Millermatic 252. I tried to put tabs on everything to make it all snap together and simplify fixturing a bit. Given the material size, I kicked the welder all the way up into spray-transfer range. This was my first time doing much spray-transfer, so don't look too closely at the welds, as there is a lot of bad undercut. Even so, everything has held together fine even in rough use.

After welding, I did some test trenching with it, then sandblasted it, primed it, and gave Giant Meta Claw a spray paint design stolen entirely from bluehog. I briefly considered sending it out to get powder coated, but couldn't see it being worth it, given it's all going to get scrapped off almost instantly.

Use

So in practice, Giant Metal Claw has worked perhaps even better than I expected. I've got extremely hard clay soil full of large rocks, and it cuts through it like it isn't even there. The basic trenching operation with it is to plunge it into the soil, then curl it around such that the tip points back to the machine, and the backplates are parallel to the ground. Then raising it all up will cause the backplates to scoop the dirt out of the trench.

Gives a trench maybe 5" wide, which I actually often find is a little bigger than I want. With not much more digging, can easily expand the trench to 10" with it. I put 5/8-11 tapped holes on the backplates for the possibility of adding trencher wings like Bro-Tek sells, but I suspect I never will bother. If you need a bigger trench, just go right to a 9" bucket instead.

I haven't done much root ripping with it yet, although it's eaten through everything I've run into while trenching without the machine even noticing it. However, if you need to pop 2"+ roots, I'd suspect you'd want something a bit more aggressive for the teeth. The lack of the beveled edge leads you to just using pure hydraulic force to pop them, and on my little machine, this only goes so far.

On the other hand, it works amazingly well at popping rocks and boulders out of the ground. I probably won't use anything else now when dealing with rocks. I used it to hook a 1000lb boulder and move it from one side of a trail to the other with no drama.

Wear

Which leads us to the topic of wear, since a lot of thinking seems to go into that. Giant Metal Claw is just made out of standard A36, and I did nothing to attempt to harden any of it. Above is a picture of the (sandblasted clean) tooth after about 2 hours of trenching. As you can see, the side edges are indeed starting to roll over.

After about another 5 hours of trenching, the tip lost all it's original sharpness, and even took a dent or two in it. And by the the paint wear, you can see the lower end unsurprisingly takes the majority of the abuse.

But even so, I don't think I'll ever wear it enough to impact performance. By time it wears down enough to be an issue, I think I'll be time ahead to just weld-build it back up and grind it back to shape. Compared to trying to work out a design with a hardened tip, this seems just fine.

Closing

Overall, I think I'm probably going to be using the my 9" bucket a lot less, and Giant Metal Claw a lot more. If you have any questions about it, feel free to ask.

Now I just have to finish Giant Metal Thumb...