The valve is called a MLS valve. It controls the rate of decent if a implement. If you have twisted the control handle out of the valve, you need to remove the valve. One question, does your tractor have a draft control. If the draft is all the way up, the three point will not operate. As Rick had suggested, make sure your aux. Remote valve is in the neutral position. I find it hard to believe that the MLS valve is the culprit here. In most cases, a faulty MLS valve will cause the three point arms to raise or lower on their own with out input from the lift control. I have had several incidents of this happening.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-Point Hitch CK30HST - 3 Point hitch stuck in up position - not the seat valve speed adjustment

- Thread starter ereilly

- Start date

- Views: 57496

More options

Who Replied?

/ CK30HST - 3 Point hitch stuck in up position - not the seat valve speed adjustment

#11

/ CK30HST - 3 Point hitch stuck in up position - not the seat valve speed adjustment

#12

FWIW the valve is a POSITION CONTROL Valve, it is not so much for speed as it is for helping to control the position of the 3 point assembly, arms, etc. Therefore if it is 'locked' closed the 3PH will not move in a downward direction, hence your current stuck 'up' state.

If I'm understanding what your stating: the valve's knob & shaft will allow you to turn the shaft all the way clockwise until it will go no further, correct?

When you try to OPEN the valve by turning it COUNTER- clockwise it will not turn at all?

If that is indeed the case your PCV is not working.

Please verify the above questions.

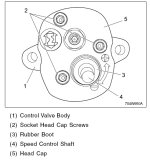

The knob and shaft that attaches to the MLS valve can turn fully clockwise until it stops. I can then turn it completely the other direction and it continues to turn until it comes loose from the MLS valve. I think that I forced this to happen but turning it with a wrench rather than hand tight. I believe I 'broke open' the metal bushing that had held it in. You can see this in the photo I posted earlier. For a better understanding of the situation see attachment CK30 MLS Valve 2, Item 4 in the list is the brass part that turns.

What is preventing the pressure from releasing?

Do I need to remove the valve and clean it?

Attachments

dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,654

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

I think that I forced this to happen but turning it with a wrench rather than

hand tight. I believe I 'broke open' the metal bushing that had held it in.

OK, so you opened up the speed control valve all the way by turning it counter-clockwise. Then

you turned it some more, causing the speed control shaft bushing to unscrew from the valve

body?

In your photo, I can see you have a wrench on the bushing. Perhaps you messed up something

inside, like the pin became unseated? You may need to take a look.

The DaeDong M27 tractors offered draft control in addition to position control, according to the manual, but no

one in the US seems to have it. That I have heard of, anyway.

Also in the manual, I see that DaeDong calls this the MLS valve, but never says what "MLS"

stands for.

/ CK30HST - 3 Point hitch stuck in up position - not the seat valve speed adjustment

#14

Hi Folks - I got some time to work on this today but need help!.

I cleaned the area carefully first. I removed the two bolts that hold the MLS valve to the main body. Once I got it loose and pulled it out a little, hyd fluid squirted out and the implement dropped. I contemplated removing the whole valve assembly to inspect but felt I might have trouble getting it back in and decided to just reattach it to see if the 3 pt goes up and down again. I tightened the two bolts carefully and evenly. I started the tractor and raised the 3 pt. The seal (it is an o ring) leaked after applying pressure. The implement did go up but I quickly moved the lever down when it leaked. It is a big leak not just drops.

Here is the problem. I tightened the bolts very tight. I am concerned about snapping off a bolt.

I am trying to figure out the correct torque for these bolts and will tighten to what the specs say.

Is there anything else you experienced mechanics can provide about how to make sure I compress the o-ring properly and make a seal? Should I try to get a new o-ring?

What is the best way to proceed? Thanks

I cleaned the area carefully first. I removed the two bolts that hold the MLS valve to the main body. Once I got it loose and pulled it out a little, hyd fluid squirted out and the implement dropped. I contemplated removing the whole valve assembly to inspect but felt I might have trouble getting it back in and decided to just reattach it to see if the 3 pt goes up and down again. I tightened the two bolts carefully and evenly. I started the tractor and raised the 3 pt. The seal (it is an o ring) leaked after applying pressure. The implement did go up but I quickly moved the lever down when it leaked. It is a big leak not just drops.

Here is the problem. I tightened the bolts very tight. I am concerned about snapping off a bolt.

I am trying to figure out the correct torque for these bolts and will tighten to what the specs say.

Is there anything else you experienced mechanics can provide about how to make sure I compress the o-ring properly and make a seal? Should I try to get a new o-ring?

What is the best way to proceed? Thanks

pedalstomper78

Gold Member

I always do new O-rings whenever I can. Heat hardens the rubber in them and makes them not seal as well. Sometimes, over-tightening an o-ring can cause more of a leak as it will defore the O-ring too much. For the torque value, this should be close enough until you find a specific number from Kioti.

Bolt torque specs for socket head cap screws for machine repair assembly bolt torq CNC

I'd check with the local service department to see if they have any information on that bolt torque.

Bolt torque specs for socket head cap screws for machine repair assembly bolt torq CNC

I'd check with the local service department to see if they have any information on that bolt torque.

SSdoxie

Elite Member

Torque on the bolts = 17 - 20 ft/lb (from my Bobcat Service Manual).

MLS stands for "Mita Load Sensing" ( whatever that means?)

MLS stands for "Mita Load Sensing" ( whatever that means?)

dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,654

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

MLS stands for "Mita Load Sensing" ( whatever that means?)

That's interesting. I knew that Bobcat had completely re-written the service manuals. I

would like to get my hands on a PDF version one of these days. BC wanted over $150 for

the PDF. One was shown to me on a laptop at the World Ag Expo.

Mita Oleodynamica of Italy is the manufacturer, as I mentioned. "Load sensing" would

make sense if it was for draft control, but that's a position-control feedback valve.

SSdoxie

Elite Member

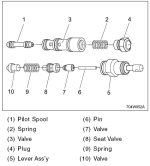

The MLS valve serves 2 purposes, both based off the load it "senses" on the 3pt. Thus "load sensing". First purpose is control rate of drop based on the load and desired drop speed - turn the knob to faster or slower to control to operator's preference. The second adjustment is neutral "band width", amount of movement/drop allowed before self-correcting. This adjustment is the Allen screw with jam nut just below were the drop speed knob connects. Here is adjustment steps for CK25-35: 1 - put 800 lb. on 3pt. 2 - Set postion lever to mid-height. 3- start engine and run at about 1500 RPM (1/2 throttle). 4- Loosen jam nut and turn screw in clockwise until 3pt starts to bounce, turn back counter-clockwise until 3pt load stops bouncing then turn additional 1/4 turn, lock jam nut.

ss4010

Silver Member

The MLS valve serves 2 purposes, both based off the load it "senses" on the 3pt. Thus "load sensing". First purpose is control rate of drop based on the load and desired drop speed - turn the knob to faster or slower to control to operator's preference. The second adjustment is neutral "band width", amount of movement/drop allowed before self-correcting. This adjustment is the Allen screw with jam nut just below were the drop speed knob connects. Here is adjustment steps for CK25-35: 1 - put 800 lb. on 3pt. 2 - Set postion lever to mid-height. 3- start engine and run at about 1500 RPM (1/2 throttle). 4- Loosen jam nut and turn screw in clockwise until 3pt starts to bounce, turn back counter-clockwise until 3pt load stops bouncing then turn additional 1/4 turn, lock jam nut.

I don't mean to Hijack this thread, but I too believe I have an issue with the MLS valve on my CT230 so it seems to make some sense to keep it in the same thread. Albeit its sort of the opposite problem. The 3 PT won't go up and the relief valve dumps when ever the position sensor on the MLS is set to lift. The tractor was working fine (for 200ish hours now) with the box blade on the back. I was working on grading a road in the community for a few hours when I went to lift the 3 PT and the hydraulic pump starts to load and the relief valve trips. Everything else hydraulic seems OK. The loader works, the remotes work (and are not in the detent position). The hydraulic level if anything is just over the full line (its had to tell as there are no level surfaces around). I'm thinking there is some sort of blockage somewhere in the MLS valve in the path to the 3pt lift cylinder causing the relief valve to dump oil. Since the machine just hit the 200 hour mark I will be conducting the 200 hour service (filters etc.) ASAP. Am I correct in thinking the only relief is in the FEL valve? Bouncing the box blade on the back I was able to get it to come up (with the 3PT set to lift), and once up the knob on the MLS valve was set not to bleed down. The tractor sat overnight with the 3 PT up with the box scraper on it so there does not appear to be a leak in the cylinder (I believe this confirms my blockage theory).

Any thoughts, ideas, suggestions? Dave, I seem to recall a similar problem on the CT230 you had for a short while in 2009?

Weather willing, I'll probably have a go at fixing it this weekend.

Thanks,

Steve

dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,654

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

Am I correct in thinking the only relief is in the FEL valve?

There is a shock-relief in the 3-pt system, set at something like 2900psi. Did you get a BC service

manual?

It does sound like you have some sort of blockage in the MLS valve.