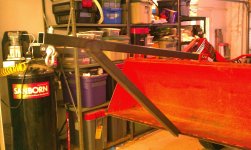

A link to some pictures of my sons new shop, 1800 square feet with 12 foot sidewalls. Two of the pics are video of the rafters going up using my 5040 Kubota and my homebuilt tractor. The homebuilt has a cage on the back we only use every couple years but it certainly works nice. If you watch the videos do the second one first then the first one as they are out of order. Once we got a system going they went pretty nice.Flickr: Alan Gage's Photostream

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My sons new shop, we put up the rafters.

- Thread starter roygage

- Start date

- Views: 4397

/ My sons new shop, we put up the rafters.

#1

jlgurr

Veteran Member

- Joined

- Oct 21, 2013

- Messages

- 1,024

- Location

- Bostic, NC

- Tractor

- Massey Ferguson GC1705, John Deere STX46

I'm certainly impressed. Not only by the ingenuity but also the new shop. :Smile: Your Kubota FEL seems to have quite a bit of lift range, is that common for a Kubota?

I'm certainly impressed. Not only by the ingenuity but also the new shop. :Smile: Your Kubota FEL seems to have quite a bit of lift range, is that common for a Kubota?

Nothing to compare it with. But am very pleased with the tractor. Bought with 675 hours on it, now nearing 1000. Son says it is the coolest thing I ever bought.

He used both it and the home-built to good effect during his build. For the few materials and time it took to build the 4x6 ft. cage on the back of the home-built it has saved us time over and over again. Every time we do something seems it is just the right height. Nice to have the railing to hand onto or lean against. Takes very little time to put on or take off.

LD1

Epic Contributor

Very nice.

If you ever plan on doing it again though, you may want to come up with a big boom pole for the FEL. When we did mine, I used an old 3-leg TV antenna tower that was about 20' long. Ratched strapped it to the bottom of the bucket, and one ratchet strap from the top of the bucket to the tip of the boom for support. Worked like a charm and took ~10 minutes to set up.

If you ever plan on doing it again though, you may want to come up with a big boom pole for the FEL. When we did mine, I used an old 3-leg TV antenna tower that was about 20' long. Ratched strapped it to the bottom of the bucket, and one ratchet strap from the top of the bucket to the tip of the boom for support. Worked like a charm and took ~10 minutes to set up.

Very nice.

If you ever plan on doing it again though, you may want to come up with a big boom pole for the FEL. When we did mine, I used an old 3-leg TV antenna tower that was about 20' long. Ratched strapped it to the bottom of the bucket, and one ratchet strap from the top of the bucket to the tip of the boom for support. Worked like a charm and took ~10 minutes to set up.

How did you do that? We bounced a bunch of ideas off each other including a boom. Our tails were pretty long due to 2 foot overhangs. I don't think we the 5040 would have handled a boom long enough to make the reach with the tractor on the outside of the building. Would you start at the far end then driving in through the door to the back with the rafter turned to the side then raise and straighten it out once high enough to clear of the wall. Or would you lift it up from the outside, set it up on the end and then once set on the walls slide it down to the far end?

Maybe drive into building and set them into place then when you run out of room for the tractor inside set the remaining ones up on the end from the outside and slip into place?

LD1

Epic Contributor

My trusses were 30' scissor trusses with a 1' overhang. Most of them were done from inside the building. Once we got to the point that you could no longer spin them to clear the walls, we could reach from the outside gable end easily.

I have no doubt your tractor would have handled it. We did them with my 3400.

We attached the boom with a 10000# rated ratchet strap. IT was the 3-leg TV tower type. put one of the flats, flat against the bottom of the bucket. Ran the strap under the tower, over the bucket, under the tower in the back, back over the bucket.

The tower itself I doubted would be strong enough to support the truss. So from the top lip of the bucket, we attached another strap out to the end of the boom. Kinda like you see support cables coming from toe top of a crane and attaching down by the counter weight.

Tractor had no trouble handling the weight and height. I would guess the trusses were ~150# and there were 6/12 pitch setting on 13.5' walls.

No pics of the boom setup, but here are the trusses. Those are 20' sections of a 40' extension ladder. So it was a ways up there.

I have no doubt your tractor would have handled it. We did them with my 3400.

We attached the boom with a 10000# rated ratchet strap. IT was the 3-leg TV tower type. put one of the flats, flat against the bottom of the bucket. Ran the strap under the tower, over the bucket, under the tower in the back, back over the bucket.

The tower itself I doubted would be strong enough to support the truss. So from the top lip of the bucket, we attached another strap out to the end of the boom. Kinda like you see support cables coming from toe top of a crane and attaching down by the counter weight.

Tractor had no trouble handling the weight and height. I would guess the trusses were ~150# and there were 6/12 pitch setting on 13.5' walls.

No pics of the boom setup, but here are the trusses. Those are 20' sections of a 40' extension ladder. So it was a ways up there.

I made a boom that fit on my bucket, I have 2" receivers welded on so I can attach different hooks. I made the framework for a steel boom out of 2" receiver tube, then u-bolted a 4x4 that was about 15' long to it. Did it all from inside the building, by wiggling the tractor around, I could get the boom in between the 2' truss spacing. My trusses were 32' long with 2' overhangs. Tied ropes on each end of the truss, helpers used those to guide truss into building and over one wall, then over the other. I also included picture of the scaffold I put on the bucket using the receivers, used that to do almost everything on the building.How did you do that? We bounced a bunch of ideas off each other including a boom.

jel1988

Gold Member

- Joined

- Feb 3, 2014

- Messages

- 316

- Location

- Elliot Lake, ON

- Tractor

- 2012 Mahindra Max 22, John Deere D120

Wouldn't some scaffolding on wheels be alot safer?

LD1

Epic Contributor

Wouldn't some scaffolding on wheels be alot safer?

that looks like wat he's got. only self powered:thumbsup:

Welderbryan

New member

Great Job