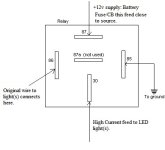

Fuses protect the wiring. It's not advisable to just put in a larger fuse for the circuit. It you need more current capacity, I would leave the original circuit wiring but use it to switch a relay. Use a larger wire to and from the relay to drive the lights with its own fuse. That would satisfy the need for more current and preserve the original wiring. (Non-destructive conversion.)

Since LEDs rely on constant current, I'm willing to bet the range of operating voltage for the lights is handled by an electronic module in the light. If so, the lights will emit the same light (lumens) no matter what voltage is applied, within the range.

Added: Also switches have a current limit. Using the original wire to switch a relay would keep the current from the switch too. 30 and 40A relays are inexpensive as well as 14 or 12 gauge wire to drive high current lighting.