deanwerden

Silver Member

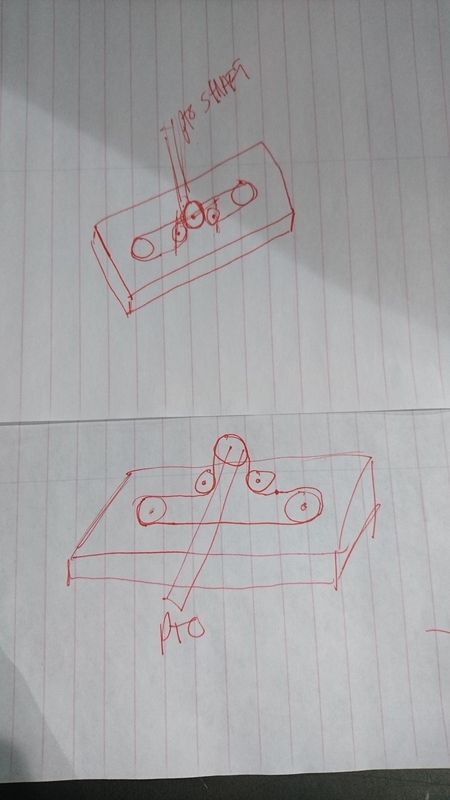

I would like to build a rotary cutter for my compact tractor , 4 feet wide but would like to use 2, 2ft blades to keep the length down, I always though a compact with a 4ft rotary cutter looked ridiculous. My idea was to either buy one gearbox and connect it to the blades with either sprockets or belts. I am wondering if a gearbox could be eliminated with the use of a double or triple v belt arrangement that wraps up 90 degrees with a hub for the pto shaft. This cutter will be used mostly for tall grass with the occasional sapling probably no more than 1". I have cut the same area of long grass with my mid mower before fully raised and It did OK but was slow going. I just see no reason why a double belt arrangement wouldn't work as my mid mower only uses one belt and will stall the engine out before the belt slips (as far as I can tell).

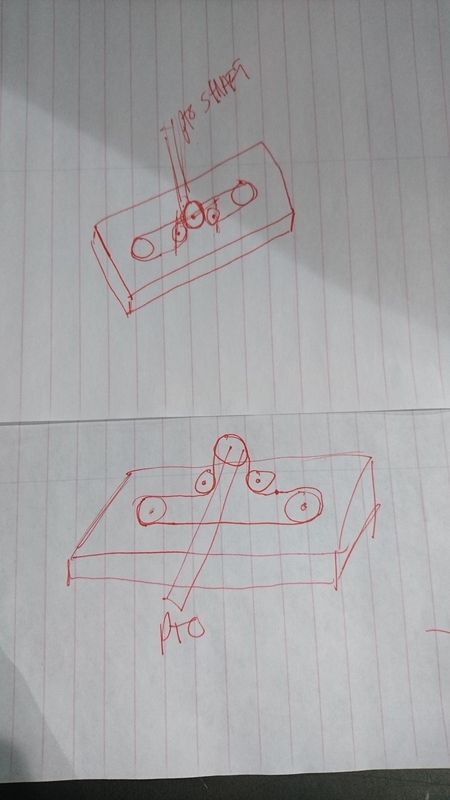

My idea is to use 2 flanged bearings spaced a few inches apart for the blade shafts, bottom will have a hub for blades and top obviously a pulley . I will then build a small platform where I can mount 2 more pillow blocks with a small stub shaft that will have a pulley on the rear and the front will have the pto shaft facing the rear of the tractor. Then I will obviously need a few idler pulleys to make the turn 90 degrees .

Thoughts? Any reason this kind of setup wouldn't work?

My idea is to use 2 flanged bearings spaced a few inches apart for the blade shafts, bottom will have a hub for blades and top obviously a pulley . I will then build a small platform where I can mount 2 more pillow blocks with a small stub shaft that will have a pulley on the rear and the front will have the pto shaft facing the rear of the tractor. Then I will obviously need a few idler pulleys to make the turn 90 degrees .

Thoughts? Any reason this kind of setup wouldn't work?