Wow. A lot here to respond to and I will not be able to cover all of it. As I noted, radiant can become a religious war...

Hard water is the root of all evil with tankless heaters. They warn about it significantly in the manuals, but with all the CYA warnings in there, it is hard to know which ones are real, and which ones are just CYA. This one is REAL. If you are running hard water through a tankless (radiant or DHW) you will have to descale with vinegar or similar on a regular schedule (probably annually, but depends on hardness). Hard water and corrosion are two separate issues. Soft water will not by itself stop corrosion, and corrosion inhibitors will not stop hard water from causing scale buildup. I suspect in a closed loop that you will not need to descale after some point as the minerals would eventually be depleted, but I am not sure how you would know when that point is reached. I doubt you can measure hardness if you have added glycol or corrosion inhibitors to a system. I have no knowledge of this.

Glycol in the system made a significant impact as I noted, but I did it for 2 reasons: Anti corrosion and system survival (freezing). I did make 1 mistake in the shop tubing in that I did not use oxygen barrier tubing. That, I believe, has lead to corrosion causing the filter to plug up and kill my flows several times. That plus if anything bad happened in the winter, it could destroy the radiant system on straight water. The house uses oxygen barrier PEX but I also run it into the garage, so another system survival issue IMO.

The amount of tubing in both the shop and the house was designed by one of the online PEX suppliers based on what I gave them for building specs including insulation, etc. The shop is a slab on grade with R10 below it and a frost-protected shallow footing design for the perimeter. There are 9 loops of 300' 1/2" PEX for a total of 2700' of tubing covering 2560 sf (32x80) in a nominal 5" slab. All lines are within a few feet of each other for total length, so they are pretty uniform. I think it was about 12" spacing, more or less. I do not believe in wasting the time to make runs laser straight as the heat don't care. So they are "straight enough" and cover all the area. It works perfectly fine. I could run a lower temp, it would just run more often. Honestly, the heater comes set for 120F and I left it there. Didn't really put a lot of thought into it, but I will say that the return water comes in pretty cool - closer to 60-65 I think (not 100% on that but sounds about right) in the shop.

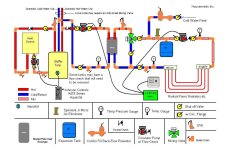

Truckdiag - The system you show is very complex and covers both DWH and radiant in a combined system and pretty clearly uses a boiler. Thus the need for the heat exchanger for that whole set of radiant loops. I didn't want to mess with that so I separated DHW from radiant. I have not dealt with boilers directly, but my understanding is that boilers heat the water to very high temps (they gotta call them BOILERS for a reason, no?) and thus require mixing valves to temper the loop water with return water so you aren't sending 180+ deg water to the floors. One of the things that makes using a tankless (or even a regular tank HW heater) work nicely for radiant, is this reduction in complexity. You don't need mixers or other complexity as you can supply more moderate temp water directly. And you don't need additional controls as the tankless lights up when it sees flow (a zone kicks on) or a tank heater lights up when the thermostat says the water temp is low enough to need heat. 120F is not that hot. It violates some radiant engineering rule as I know they like the outgoing and returning water temps to be only like 20 deg different, but it still works. Again that holy war issue...

Zone flow indicators are nice as they help you ensure that you are getting flow in each zone, and you can help balance the zones better. I used a Calleffi manifold in the house system like the link below after realizing how helpful it would have been in the shop, which I did first:

6687M5S1A - Caleffi 6687M5S1A - 1-1/4" TwistFlow Manifold w/ Temp Gauge (11 Outlets)

As for zones, put zones where you want to control the temp. Period. In the shop, it is split in 2, so I have 2 zones. The front is where the garage doors are, so that is best on it's own zone. It is a bit big for only one zone, too. The house is split by what made sense. The great room/kitchen is all one zone. It's one big room, so one zone. Each BR and full bath is it's own zone. And then the remainder as they made sense per the layout. I ended up with 13 total (and 2 got trashed during construction, so 11 in the end), but our house is in the 3600 sf size zone, so it is significantly larger than what you (ovrszd) is building.

Another thing to remember about thermostats is that you should not really trust the readings from them. What I mean is that if you mount 5 thermostats right next to each other you would get 3-5 different temp readings from them. So use the actual number as a guideline to start. Try 68F for example. Not warm enough? Raise it a degree or two, depending on if it seems just a little cool or worse than that. Wait, and check again in a day. Adjust again if needed. When you find the right temp for that Tstat, write it down. One room could be set at 72 and the next room at 70 and they could feel the same. If you replace a tstat, you may need to find a new setpoint. These are not precision calibrated NIST traceable units. They only cost a few bucks... Plus different floor coverings make a difference. So set them where it ends up feeling about right for comfort, and ignore the actual number.

For getting air out, I used a pump (basically a portable submersible pump) and recirculated water through the system, isolating one loop at a time using a large tub for water. the air comes out pretty quick. the air separator takes out minor residual air, but you should check to make sure the pressure in the system stays up for a few days, as you may need to repressurize a bit to compensate for eliminated air. If you have significant air in the system or in a loop, you don't get flow. If you have a nicely heated floor, you have flow. This is where the flow indicators are nice to help debug.

I do believe that tankless heaters are higher pressure drop than boilers (probably - no firsthand experience) based on the relatively low flows I am seeing. i also belive that they make for a simple system and installation.

This is why I do not often post on some of these technically complex issues so much anymore. I feel the need to fully explain what I know and have done, and the reasoning behind it, and it gets to be quite long and takes a lot of time. Plus my knowledge comes from my own experience and reading, which is limited, by definition. I am not a fluids or HVAC engineer (though I am a mechanical/polymer engineer...). There are rules that are sacrosanct (gravity seems pretty solid) and there are rules with more flex (the temp you feed a radiant slab) ...Trying not to turn TBN into a chore, but I also feel the need to share and give back where I can.

If you want more details than you can handle or care about, my house build blog is in my Sig below. Go crazy. It has tons of pics and all of my complaining about crappy subs plus a lot of detail.