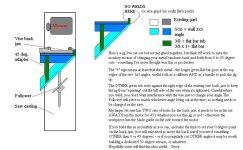

HF Horizontal/vertical Bandsaw item 93762.

Metal Band Saw - Horizontal/Vertical Metal Band Saw

This is the original model, or close to it. They also sell item 62377 interchangeably, but more on that later. Item 93762 is the model shown on the website, and is easily identified by the squared upper corner on the main saw body by the blade tension knob. After a few adjustments to blade roller guides, I have this saw cutting nice clean square cuts. I'm happy with the purchase.

Now more about 62377 which was my original purchase a few weeks ago. I did a lot of reading about both models before buying, and while there are quite a few minor differences, I didn't think either had a clear advantage over the other. 93762 is a clone of many other brands though, including Grizzly. When I bought my saw, the store only had a 62377 so I took it. After assembling it, I tried to get it adjusted for close to 5 hours over a couple of days. Eventually I realized the list of deficiencies was too much for my taste:

- Upper wheel had to be shimmed inwards until nearly dragging on the cast body.

- Lower wheel had to be shimmed outwards, extending off the shaft 1/4".

- Saw drop tension spring adjustment rod was drilled and tapped at a 20* angle for the eye-bolt, making it difficult to rotate.

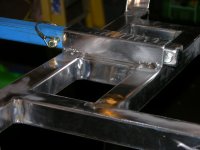

- Gear box leaked non stop even after removing cover and cleaning. Cover material is too thin and only has 4 corner bolts to attach so it bows instead of sealing.

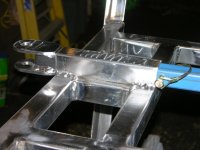

I did get this first saw to hold a blade and cut square, but with the wheels shimmed so far I thought it was stressing everything. The gear box could have been sealed semi-permanently with gasket sealer or by making a heavier gauge cover plate, but I thought that shouldn't be needed on a new tool. Plus the 93762 model has 6 bolts in the gear box cover for a tighter fit. So I called and found a couple other nearby stores that had the 93762 model in stock. I re-boxed the original saw and exchanged it. The store manager exchanged the saw without question, and said he was surprised about the issues I had with mine. He said they sell quite a few and never have issues with either model, so hopefully I got a lemon on the first try. I will say a couple of the nicer features on the 62377 are the rubber feet and better wheels. I also picked up a spare blade while I was there, since they had bi-metal, made in USA blades in stock.