redheelerdog

Silver Member

- Joined

- May 12, 2018

- Messages

- 108

- Location

- The Sticks of Montana

- Tractor

- 1944 Farmall M 2007 AGCO ST34

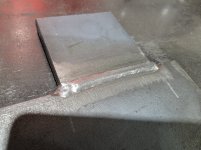

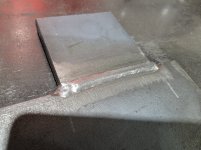

Below are some pictures of welds made with the Miller 255 pulse MIG (Grader Scraper build)

I have had the machine for about 3 weeks and it is amazing.

Starting to get the feel for the pulse settings. The noise is quite different but I am getting used to it.

These are just flat welds, and they are amazingly clean in an as welded condition.

030" ER70-S6 C10 gas (90 Agon/10 CO2)

I have had the machine for about 3 weeks and it is amazing.

Starting to get the feel for the pulse settings. The noise is quite different but I am getting used to it.

These are just flat welds, and they are amazingly clean in an as welded condition.

030" ER70-S6 C10 gas (90 Agon/10 CO2)