WinterDeere

Super Star Member

- Joined

- Sep 6, 2011

- Messages

- 12,871

- Location

- Philadelphia

- Tractor

- John Deere 3033R, 855 MFWD, 757 ZTrak; IH Cub Cadet 123

@Sawyer Rob had posted this in another thread:

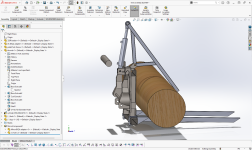

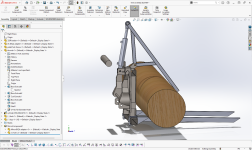

Serendipitous timing, I was both contemplating a grapple and setting up to modify my own 3-point forks for JDQA loader use. One of my primary loader uses is moving logs, all 15 foot lengths, and I do this using a pair of chain chokers arranged as a sling. It works great, but requires a lot of hopping off the seat, and it's not always the safest operation unhooking the chokers while piling logs.

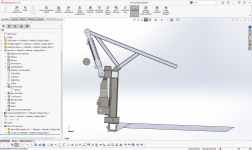

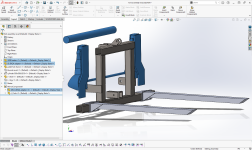

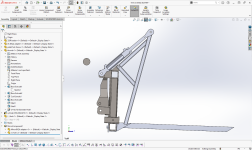

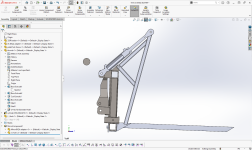

Looking at @Sawyer Rob's rig, I started playing with the idea of using the top link pin on my 3-point fork frame for mounting of a cylinder to control a thumb. I won't need this top link pin when using the forks on the loader, so it's available. It appears all I need is an extra set of tangs welded to the top tube of the fork frame, to let the thumb pivot:

(click for full size)

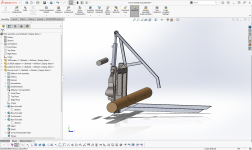

The tube floating in air is the cross-member on the loader frame, need to make sure the cylinder can't collide with that. Shown here with an 18" log, but tested with 6" to 24".

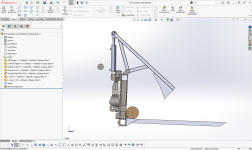

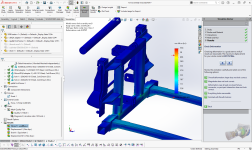

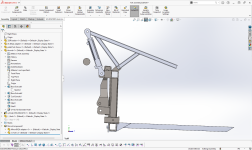

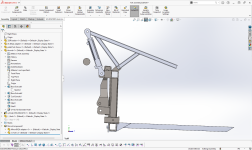

No binding or collisions in full range of travel:

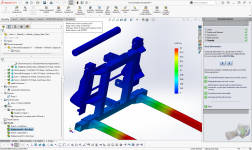

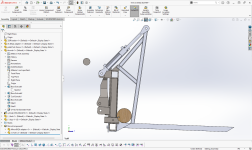

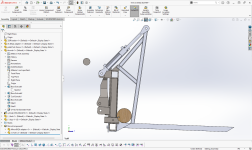

Only potential problem I see, other than needing some more work to pick metal sizing and thicknesses, is that the thumb may tend to lift small logs off the forks due to forming a "V" with the back of the frame at small diameters:

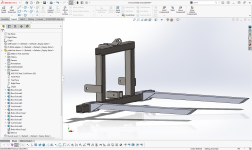

I thought I could tune this out with some fiddling of the section lengths on the thumb, but this is the best I've been able to do without either giving up max capacity or causing a potential collision / bending metal between the cylinder and loader cross member or cylinder to thumb spine.

If someone can give me a good guess on square tube size and gauge for that thumb, it might save me some FEA simulation work. The cylinder is only 50mm bore, so around 7850 lb. at my tractor's 2500 psi working pressure. Weight is a concern, as this fork frame already weighs a lot, and I'm often fighting for more loader capacity when moving logs.

It has a thousand uses, I use it all the time, it's been one of my "best buys".

SR

Serendipitous timing, I was both contemplating a grapple and setting up to modify my own 3-point forks for JDQA loader use. One of my primary loader uses is moving logs, all 15 foot lengths, and I do this using a pair of chain chokers arranged as a sling. It works great, but requires a lot of hopping off the seat, and it's not always the safest operation unhooking the chokers while piling logs.

Looking at @Sawyer Rob's rig, I started playing with the idea of using the top link pin on my 3-point fork frame for mounting of a cylinder to control a thumb. I won't need this top link pin when using the forks on the loader, so it's available. It appears all I need is an extra set of tangs welded to the top tube of the fork frame, to let the thumb pivot:

(click for full size)

The tube floating in air is the cross-member on the loader frame, need to make sure the cylinder can't collide with that. Shown here with an 18" log, but tested with 6" to 24".

No binding or collisions in full range of travel:

Only potential problem I see, other than needing some more work to pick metal sizing and thicknesses, is that the thumb may tend to lift small logs off the forks due to forming a "V" with the back of the frame at small diameters:

I thought I could tune this out with some fiddling of the section lengths on the thumb, but this is the best I've been able to do without either giving up max capacity or causing a potential collision / bending metal between the cylinder and loader cross member or cylinder to thumb spine.

If someone can give me a good guess on square tube size and gauge for that thumb, it might save me some FEA simulation work. The cylinder is only 50mm bore, so around 7850 lb. at my tractor's 2500 psi working pressure. Weight is a concern, as this fork frame already weighs a lot, and I'm often fighting for more loader capacity when moving logs.

Last edited: