xcgreene

Platinum Member

I'll start by saying this surely isn't necessary, but I enjoy the tinkering.

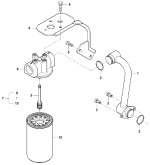

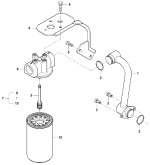

I stumbled over this hydraulic filter magnet while looking through a manual for the DKse tractor's twin from Australia, the EX. In the exploded parts view of the filter housing there was part #T4260-38841 "magnet assembly". See #9 here

Item #9 is not present in the DKse manual. All else appears the same. Looking that part number up in the googles, I also found it belongs to other relatives of the Kioti DKse, those being the Cub cadet tractors 8354, 8404, and 8454. Everything else on these tractors seemed so similar, I wondered if this magnet would fit on my DKse.

So, despite only being at 300hrs at the time, and not being able to help myself in waiting until the 400hr service, I removed my DKse's hydraulic filter, and looked up into the aluminum housing which the filter screws onto. You can see here in this next photo the 8.5mm x 16mm deep hole, already drilled (or cast), but without threads.

So after seeing this hole, and the magnet assembly only costing $35.32 shipped from Messicks, I had to order one. Upon delivery, I could have a look at the thread size. M10 x 1.25, perfect for the hole at hand. At this point coincidence is off the market.

Also proved plenty of clearance when compared to the filter it would be inside of.

So, I grabbed a starter tap and put it to work, making sure not to get metal particles about. Went very smoothly and cut great threads. Using blue locktight, I screwed the magnet in. At this point, my concerns of clearance to allow good oil flow were minimized.

Fast forward, having reached the 400hr service, I have changed my filters and had a chance to take a look at the magnet. Again, important to note that the magnet had 100hrs on it at this point. But I can clearly see it has picked up fine particles after the filter. You can see the collection here in this photo.

Noting this metal powder collection on the new filter magnet, here's a picture of the transmission drain magnet at the time of this same service. Very little fuzz, just a few bits.

Now, one could certainly say I've just traded locations of where the metal powder accumulates. But, I would argue that if this powder has changed locations of where it accumulates, then this new location is more effective. Every ounce of oil that is pumped must pass within 1 inch of this new magnet, where the drain plug magnet is only gathering from the general vicinity.

During these 100hrs, I have noticed no differences in operational speeds or sound. This includes heavy use of the backhoe, a large degree of loader work, and field mowing.

I'll finish this off by again saying that I certainly don't think this is a "must do" for your dkse tractors out there. For me, its just another useful indicator that will help keep the oil in its best shape possible.

All said and done, I've got 35 bucks and about 20 minutes of install time invested.

Thought some of you folks out there might find it interesting.

I stumbled over this hydraulic filter magnet while looking through a manual for the DKse tractor's twin from Australia, the EX. In the exploded parts view of the filter housing there was part #T4260-38841 "magnet assembly". See #9 here

Item #9 is not present in the DKse manual. All else appears the same. Looking that part number up in the googles, I also found it belongs to other relatives of the Kioti DKse, those being the Cub cadet tractors 8354, 8404, and 8454. Everything else on these tractors seemed so similar, I wondered if this magnet would fit on my DKse.

So, despite only being at 300hrs at the time, and not being able to help myself in waiting until the 400hr service, I removed my DKse's hydraulic filter, and looked up into the aluminum housing which the filter screws onto. You can see here in this next photo the 8.5mm x 16mm deep hole, already drilled (or cast), but without threads.

So after seeing this hole, and the magnet assembly only costing $35.32 shipped from Messicks, I had to order one. Upon delivery, I could have a look at the thread size. M10 x 1.25, perfect for the hole at hand. At this point coincidence is off the market.

Also proved plenty of clearance when compared to the filter it would be inside of.

So, I grabbed a starter tap and put it to work, making sure not to get metal particles about. Went very smoothly and cut great threads. Using blue locktight, I screwed the magnet in. At this point, my concerns of clearance to allow good oil flow were minimized.

Fast forward, having reached the 400hr service, I have changed my filters and had a chance to take a look at the magnet. Again, important to note that the magnet had 100hrs on it at this point. But I can clearly see it has picked up fine particles after the filter. You can see the collection here in this photo.

Noting this metal powder collection on the new filter magnet, here's a picture of the transmission drain magnet at the time of this same service. Very little fuzz, just a few bits.

Now, one could certainly say I've just traded locations of where the metal powder accumulates. But, I would argue that if this powder has changed locations of where it accumulates, then this new location is more effective. Every ounce of oil that is pumped must pass within 1 inch of this new magnet, where the drain plug magnet is only gathering from the general vicinity.

During these 100hrs, I have noticed no differences in operational speeds or sound. This includes heavy use of the backhoe, a large degree of loader work, and field mowing.

I'll finish this off by again saying that I certainly don't think this is a "must do" for your dkse tractors out there. For me, its just another useful indicator that will help keep the oil in its best shape possible.

All said and done, I've got 35 bucks and about 20 minutes of install time invested.

Thought some of you folks out there might find it interesting.