Roger G

New member

I have a new 2010 5600 Toolcat that had a hydraulic line fail after 13 months and 530 hours of use. Hydraulic leak showed up as visible drips all along the center frame front to rear. Traced the leak to a hose coming out of the pump next to the exhaust pipe of the engine. The leak was dripping down to the top of the center frame and spreading front to rear on the center frame. The heat of the engine had baked the hose at the crimp connection causing the leak. The local Bobcat dealer said that they had replaced those hoses before and that they were a pain to change as the only way to remove the hose was to pull the engine due to the tight space between pump and the engine's heat shield. They said I would have to bring the machine in to their shop to have it repaired.

The hose goes from the pump down to a block with 7 hoses attached.

So I ordered a new hose; purchased a one inch crows foot wrench; used a chisel to remove the plastic washer next to the nut so that the crows foot tool would slide on the nut; turned the ratchet; loosened the nut with ease; did the same with the nut on the pump; and had the hose off in five minutes. Took the new hose and pushed the bottom end down in between the pump and engine holding the hose in a curve shape so that it would slide across the top of the center frame and slid it back to the block. The hose has a push in connector for each end. I had the new hose installed in less than five minutes.

I suspect all Toolcats with this design will have this hose baked by the engine heat causing the hose to crack and leak at the crimp fitting next to the pump.

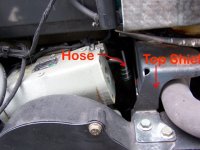

First photo shows hose coming out of pump next to top of engine. Second photo shows hose connecting to block. All locations visible when you raise the bed.

The hose goes from the pump down to a block with 7 hoses attached.

So I ordered a new hose; purchased a one inch crows foot wrench; used a chisel to remove the plastic washer next to the nut so that the crows foot tool would slide on the nut; turned the ratchet; loosened the nut with ease; did the same with the nut on the pump; and had the hose off in five minutes. Took the new hose and pushed the bottom end down in between the pump and engine holding the hose in a curve shape so that it would slide across the top of the center frame and slid it back to the block. The hose has a push in connector for each end. I had the new hose installed in less than five minutes.

I suspect all Toolcats with this design will have this hose baked by the engine heat causing the hose to crack and leak at the crimp fitting next to the pump.

First photo shows hose coming out of pump next to top of engine. Second photo shows hose connecting to block. All locations visible when you raise the bed.