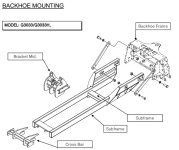

I think that I have decided to build a subframe, if I attach it to the FEL brackets

and to some brackets by the rear axle would I still want to attach to the top link?

It is there and strong. Why not use it? My own personal hoe, which has served me well for that past dozen

years, connects to FIVE points on the back of the tractor-side subframe. I still get a bit of flex.

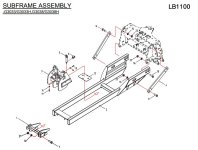

In choosing the steel for the main structural member of your subframe under the hoe, there are several

factors to consider: do I have some steel already that I do not have to buy? Great if you can reuse

some steel that you salvaged, or already bought in bulk.

If you have purchased nothing so far, then a round-cross-section tube will be the strongest in all

directions, per unit pound. Since you are concerned about up-down strength, not left-right, a deep-

section beam is better usable strength per unit of weight. I-beams are ideal for this kind of strength, but

not ideal to weld to, on the sides. The best shape compromise is a C-channel with thick web. This is strong,

easy to weld to on one side, and commonly available.

If you look at OEM designs, the good examples use solid plate, often as much as 3/4" thick. That

material is easier to machine in a factory setting, IMO, and weld to, if you have to weld both sides. It

will weigh and cost a lot more than channel, however. You and I may struggle with the weight of

3/4" plate, but the factory likely does not.