ggtechman7

New member

I have 23 HP Rhino, and the 3 point contol valve did not work, it had a broken shaft, so I ordered a new one from Homier at parts.farmprotractors.com. I installed it and with lever in rear position I hear the hydraulic pump cavitating, and in the forward position it lifts the bucket.

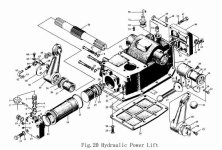

I am not sure what to check now? The hydraulic power lift is like the farmpro, and I have a drawing of it, but I do not understand how it functions?

I am not sure what to check now? The hydraulic power lift is like the farmpro, and I have a drawing of it, but I do not understand how it functions?