Jim Timber

Veteran Member

Three years ago, I installed an extra 2-spool valve on my rear fender for running my 3pt stump grinder. It was super intuitive to manipulate the cutter head with the twin levers and being hasty I never plumbed it into the tractor so I was running it off the rear (3rd) SCV which required my holding the lever to provide power to the valve. It worked well enough, but then I had to unhook my hydraulic top link to use the stump grinder and then lost some of my adjustability for larger stumps when doing that. The next year, I made a hydraulic tilt link and then I had a choice of either having TnT, or having my grinder connected. Couldn't use my TnT to help connect implements from the rear because then I'd screw up the 3pt hitch function if I bungee'd the SCV. I kept saying I was going to fix it one of these days and never got around to it because of the hassle/expense of renting a trailer. Well, that changed this Spring when I finally bought a trailer. The tractor came home and I got started!

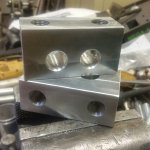

Rather than using a diverter and the single spool valve I'd bought years back, I got a 2-spool with float detent for my TnT so I have float on my top link should the desire arise.

![20180527_190842[1].jpg 20180527_190842[1].jpg](https://www.tractorbynet.com/forums/data/attachments/493/493729-8f0bdc540b5ffc9cd866e14dec7e6249.jpg)

I also used QD connections so I can remove the hydraulic top link if I want to as well (I haven't put it in since finishing the plumbing).

Since I had PB circuits between two valve bodies at the aft of the machine anyway - I put a QD connection between them and now have Power Beyond for electro/hydraulic/remote operation of my skidding winch. Which cost me all of $20 for the pair of connectors.

Also, needing to gang two valve body's tank drain ports and connect them with the tractor sump, I used that junction to add another T port to the aft of the machine for future use with the skidding winch, hydraulic motors, or what have you.

![20180607_175354[2].jpg 20180607_175354[2].jpg](https://www.tractorbynet.com/forums/data/attachments/499/499910-51555b1c293c89f2e610ff1d9b8d01e3.jpg)

I still need to build my proper right-angle brackets for the stump grinder's valve body QD's, but the valves are all plumbed in and everything works. Force of habit bit me in the bum as soon as I started the tractor today: I've become so used to using my stump grinder valves for TnT that I instinctively reached for the lower valve's controls and proceeded to dump hydraulic fluid on the driveway when I meant to level out the tiller (which served quite nicely as a seating bench for the whole procedure). Since that's really the only mishap of the entire up-fit, I'm pretty pleased. :thumbsup:

Since that's really the only mishap of the entire up-fit, I'm pretty pleased. :thumbsup:

To anyone wondering "Why not just add the 4th SCV from the factory?": That's got a couple answers. First, I'm not left handed. The fender mounted valve actually places the controls in a very comfortable position for my right hand while I'm turned 90 degrees in the seat running the grinder. Second, it's $1300 for the second rear SCV kit from the factory. I have 2 diverters (power SSQA control, and 3rd function on my loader), and 2 extra 2-spool valves with all the plumbing/fittings between the whole works for less than one additional factory rear SCV. Another reason to go with fender mounted valves in my case is that the tractor itself is big enough that I can't reach in and operate the factory rear SCV controls and still see the 3pt hitch without being on the tractor. Now I can stand on the ground and fine-tune my tilt link to line up with unevenly situated implements.

Rather than using a diverter and the single spool valve I'd bought years back, I got a 2-spool with float detent for my TnT so I have float on my top link should the desire arise.

![20180527_190842[1].jpg 20180527_190842[1].jpg](https://www.tractorbynet.com/forums/data/attachments/493/493729-8f0bdc540b5ffc9cd866e14dec7e6249.jpg)

I also used QD connections so I can remove the hydraulic top link if I want to as well (I haven't put it in since finishing the plumbing).

Since I had PB circuits between two valve bodies at the aft of the machine anyway - I put a QD connection between them and now have Power Beyond for electro/hydraulic/remote operation of my skidding winch. Which cost me all of $20 for the pair of connectors.

Also, needing to gang two valve body's tank drain ports and connect them with the tractor sump, I used that junction to add another T port to the aft of the machine for future use with the skidding winch, hydraulic motors, or what have you.

![20180607_175354[2].jpg 20180607_175354[2].jpg](https://www.tractorbynet.com/forums/data/attachments/499/499910-51555b1c293c89f2e610ff1d9b8d01e3.jpg)

I still need to build my proper right-angle brackets for the stump grinder's valve body QD's, but the valves are all plumbed in and everything works. Force of habit bit me in the bum as soon as I started the tractor today: I've become so used to using my stump grinder valves for TnT that I instinctively reached for the lower valve's controls and proceeded to dump hydraulic fluid on the driveway when I meant to level out the tiller (which served quite nicely as a seating bench for the whole procedure).

To anyone wondering "Why not just add the 4th SCV from the factory?": That's got a couple answers. First, I'm not left handed. The fender mounted valve actually places the controls in a very comfortable position for my right hand while I'm turned 90 degrees in the seat running the grinder. Second, it's $1300 for the second rear SCV kit from the factory. I have 2 diverters (power SSQA control, and 3rd function on my loader), and 2 extra 2-spool valves with all the plumbing/fittings between the whole works for less than one additional factory rear SCV. Another reason to go with fender mounted valves in my case is that the tractor itself is big enough that I can't reach in and operate the factory rear SCV controls and still see the 3pt hitch without being on the tractor. Now I can stand on the ground and fine-tune my tilt link to line up with unevenly situated implements.