Henry

Silver Member

790 - Needs a little more \"umph - Got suggestions?

Gentlemen and elightened Tractor Ladies,

I've had my 790 for several years now and really love it. Currently, I use it mostly for mowing and relatively light loader work without any issues.

However, I've got a big driveway project coming up this summer and I'd really like to be able to do some snow plowing work next winter.

While I know that I ought to purchase a box blade for the driveway work and a reversable back-blade for the snow-plowing, I need some adivse on how to improve the performance of the loader and the basic abilities to handle heavier work.......

I need some advise on "umph" upgrades. Here's my initial thoughts & questions:

<ul type="square"> [*]Replace my turf tires with R4's - What are the basic considerations for doing this?

[*]Add a tooth-bar to my loader for the driveway work - Are they easy to install for a do-it-your-selfer?

[*]Adding shims to the hydraulic system scares me - If I do this, am I risking a major failure?

[/list]

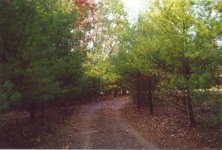

Here's a picture of my driveway.

It's about 300 feet long, with a gentle up hill slope. It's gotten badly rutted and needs to be resurfaced (with gravel) and some sloping done to handle the drainage issues.

Gentlemen and elightened Tractor Ladies,

I've had my 790 for several years now and really love it. Currently, I use it mostly for mowing and relatively light loader work without any issues.

However, I've got a big driveway project coming up this summer and I'd really like to be able to do some snow plowing work next winter.

While I know that I ought to purchase a box blade for the driveway work and a reversable back-blade for the snow-plowing, I need some adivse on how to improve the performance of the loader and the basic abilities to handle heavier work.......

I need some advise on "umph" upgrades. Here's my initial thoughts & questions:

<ul type="square"> [*]Replace my turf tires with R4's - What are the basic considerations for doing this?

[*]Add a tooth-bar to my loader for the driveway work - Are they easy to install for a do-it-your-selfer?

[*]Adding shims to the hydraulic system scares me - If I do this, am I risking a major failure?

[/list]

Here's a picture of my driveway.

It's about 300 feet long, with a gentle up hill slope. It's gotten badly rutted and needs to be resurfaced (with gravel) and some sloping done to handle the drainage issues.