MotorSeven

Elite Member

I have been thinking about a bridge over our creek for 7-8 years. It's 50+' bank to bank...so it was a lot of thought.

I came across a welded bridge frame at an auction. It was built out of mobile home frame(10" 1/8th I-beam) 60' long, 45" wide & it looked sturdy enough. I cut it in half, to load it and get it home where I welded it back together. I used the Kioti to pull it down to the creek. I attached a cable in a Polpar tree on the opposite bank and pulled it across with the tractor(bridge on it's back). When I tried to turn it over it pretzled(yes my splice held), so I pulled it back across and used the FEL to straighten it back out. I have a 25KW pto generator, so I hooked it up and used my Millermatic 210 to weld in 10" I-beam cross braces every 6'(the original one's were 4" and real thin metal) I added a support under the bridge angles for extra support.

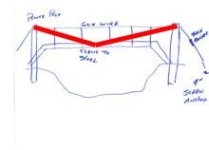

The second try was succesfull, so I poured concrete footers at each end and bolted the frame to the footers. 2x6x20 PT(120') was lag bolted to the top of the bridge I-beams, then 4' 2x6 PT planking screwed down with 3" Torx deck screws. This really made it more stable, but I am still going to sink 2 utility poles at each end, run a cable across and stanchon the bridge is several places with cable. Only then will I drive my wheeler across. So far I have about $500 in it(and a ton of time:thumbsup . This creek floods several times a year, so that is why it is so high...to keep debris from catching it and pulling it down stream.

. This creek floods several times a year, so that is why it is so high...to keep debris from catching it and pulling it down stream.

Welding it back together:

Note the tiny cross braces:

On the road to the creek:

I came across a welded bridge frame at an auction. It was built out of mobile home frame(10" 1/8th I-beam) 60' long, 45" wide & it looked sturdy enough. I cut it in half, to load it and get it home where I welded it back together. I used the Kioti to pull it down to the creek. I attached a cable in a Polpar tree on the opposite bank and pulled it across with the tractor(bridge on it's back). When I tried to turn it over it pretzled(yes my splice held), so I pulled it back across and used the FEL to straighten it back out. I have a 25KW pto generator, so I hooked it up and used my Millermatic 210 to weld in 10" I-beam cross braces every 6'(the original one's were 4" and real thin metal) I added a support under the bridge angles for extra support.

The second try was succesfull, so I poured concrete footers at each end and bolted the frame to the footers. 2x6x20 PT(120') was lag bolted to the top of the bridge I-beams, then 4' 2x6 PT planking screwed down with 3" Torx deck screws. This really made it more stable, but I am still going to sink 2 utility poles at each end, run a cable across and stanchon the bridge is several places with cable. Only then will I drive my wheeler across. So far I have about $500 in it(and a ton of time:thumbsup

Welding it back together:

Note the tiny cross braces:

On the road to the creek:

Last edited: