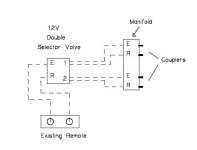

There is the capacity to add separate remotes by installing another double spool control valve into the circuit.

Whether the new valve goes before or after the existing is a question of where there is room to mount it.

Here is a simple description.

Locate the pressure delivery line and it can be cut into and directed to the input side of the new spool valve set.

Each new remote is coupled onto the spool valve, I use 1/2 inch double braid high pressure hydraulic hose and re-useable (IE able to fit yourself) connectors, and whatever standard of quick release coupling is your preference.

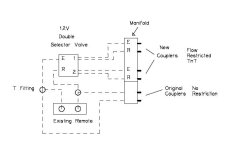

The pressure exhaust line from the new spool set is then connected to the inlet of the existing spool valve set servicing the OEM outlets. The low pressure (bypass) outlet from the new spool valve set is connected without restriction to the return line (sometimes it can be teed into the oOEM bypass/return) line to the hydraulic oil storage tank or a new connection directly into the top of the tank again no restriction.

The exhaust line from the OEM spool is left to return to tank as is the pressure relief bypass if there is a separate one.

BUT it is essential that a "power beyond valve is fitted to the spool valve that first receives the oil nfrom the pump. It is usually easier to fit this to the new spool valve. What this does is to permit the pressure relief valve in the first valve in the circuit to dump excess pressure back into the storage tank . If this is not fitted rather than the point of relief being the cumulative pressure setting of the two sets of spool valves it is in fact amultiple of the values they are set at, leading to damage either to the pump or some other part of the circuit.

The advantage of this setup is you have two double ie 4 remote connections and if you want flow restriction, the restrictors can be fitted into the line from the couplings to the device/cylinder being used.

You could fit single, double, triple or quad spool valve set this way and if of a mind you can later fit a third spool set remembering that every spool set in the line has to have apower beyond valve fitted with a low pressure unrestricted return to the tank.

May sound complicated but is more useful than a director valve/s. I feel like I need to be an octopus to manage director valves.

This setup is very useful if adding a front end loader to a tractor and by using a quad spool valve setup then the 4-in-1 bucket the crowd ,the lift and even a further outlet to power a fourth implement/ tool on the FEL arms.

Most aftermarket spool valves will have the facility for a power beyond valve.

Old age and a grumpy disposition mean that I have not yet mastered the art of sending pics.