niemeyjt

Silver Member

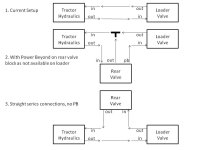

I want to add a couple of rear double acting spool valves to my Kubota B1750 with KBF200 Loader.

Currently, I have the detatchable loader plumbed into the hydraulics, so I will fit it in there in series. When loader is detatched, I there is a loop of pipe that connects hydraulic pipe output and input which needs to be retained in some form obviously. My question is over the order of connection - should the flow be

1. pump -> loader -> rear valves -> pump

or

2. pump -> rear valves -> loader -> pump

or

3. does not matter (in which case I will do what is neatest, probably 2)

As I say, the loader has only two pipes to the tractor - feed and return.

TIA

J

Currently, I have the detatchable loader plumbed into the hydraulics, so I will fit it in there in series. When loader is detatched, I there is a loop of pipe that connects hydraulic pipe output and input which needs to be retained in some form obviously. My question is over the order of connection - should the flow be

1. pump -> loader -> rear valves -> pump

or

2. pump -> rear valves -> loader -> pump

or

3. does not matter (in which case I will do what is neatest, probably 2)

As I say, the loader has only two pipes to the tractor - feed and return.

TIA

J