bcarwell

Gold Member

Hi all,

I am building a toothbar for my Kubota 7500 FEL. It has limited power (24HP, 600 lbs lift in "theory"). I have lots of rock I need to get out of the pasture and am told I may not have the power to run a conventional rock bucket. So until I try I don't know how many teeth on a tooth bar I could handle, how long they could be before I bogged down rooting rocks out, etc.

So I saw the need for a tooth bar where I could space the teeth experimentally easily to see what works best and in whatever job I'm doing- rooting and picking up a few big rocks with a few longer teet, scraping up more smaller rocks with smaller, closer spaced teeth, etc. And I might also like to just add two long teeth to serve as two forklifts for lifting a small stump or whatever.

So what I'm thinking of is the following I'd appreciate some comments on regarding feasibility, stupidity, etc. I can't afford lots of different implements and thought with this setup, I could fabricate all kinds of different teeth as needed and install them quickly.

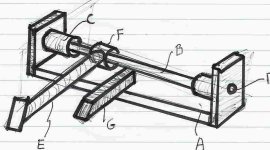

Basically its a regular toothbar plate maybe 3/8" at "A". The ends are bolted through holes in the FEL at "D" just like a regular add-on toothbar plate near the front lip of the bucket. A pipe "B", maybe 1 1/2 inch is supported by two slightly larger short pipe pieces "C" welded to the end brackets of the toothbar. I then add as many teeth E as desired and of desired length for the given application by sliding them onto the pipe B before installing the toothbar plate. The important point (not shown) is that I can also slide short lengths of pipe like C onto the pipe B to serve as spacers between the teeth E so as to space the teeth any desired distance apart.

I also might weld some permanent shorter teeth (only one shown as "G") to serve as conventional toothbar teeth since I've already incurred the cost of the toothbar A (and also in case the design of the adjustable teeth is a disaster). If I'm digging up big rocks, I might just put two longer teeth E on. If I'm scraping shorter rocks I might, instead, use more teeth spaced closer together to act like a conventional rockbucket teeth where the dirt can fall between the teeth and I can tip the bucket up to deposit the rocks in the FEL bucket.

Anyway, hopefully you get the crude idea (sorry about the lousy drawing).

I'd appreciate any comments, suggestions, or indications I'm certifiably nuts.

Bob

I am building a toothbar for my Kubota 7500 FEL. It has limited power (24HP, 600 lbs lift in "theory"). I have lots of rock I need to get out of the pasture and am told I may not have the power to run a conventional rock bucket. So until I try I don't know how many teeth on a tooth bar I could handle, how long they could be before I bogged down rooting rocks out, etc.

So I saw the need for a tooth bar where I could space the teeth experimentally easily to see what works best and in whatever job I'm doing- rooting and picking up a few big rocks with a few longer teet, scraping up more smaller rocks with smaller, closer spaced teeth, etc. And I might also like to just add two long teeth to serve as two forklifts for lifting a small stump or whatever.

So what I'm thinking of is the following I'd appreciate some comments on regarding feasibility, stupidity, etc. I can't afford lots of different implements and thought with this setup, I could fabricate all kinds of different teeth as needed and install them quickly.

Basically its a regular toothbar plate maybe 3/8" at "A". The ends are bolted through holes in the FEL at "D" just like a regular add-on toothbar plate near the front lip of the bucket. A pipe "B", maybe 1 1/2 inch is supported by two slightly larger short pipe pieces "C" welded to the end brackets of the toothbar. I then add as many teeth E as desired and of desired length for the given application by sliding them onto the pipe B before installing the toothbar plate. The important point (not shown) is that I can also slide short lengths of pipe like C onto the pipe B to serve as spacers between the teeth E so as to space the teeth any desired distance apart.

I also might weld some permanent shorter teeth (only one shown as "G") to serve as conventional toothbar teeth since I've already incurred the cost of the toothbar A (and also in case the design of the adjustable teeth is a disaster). If I'm digging up big rocks, I might just put two longer teeth E on. If I'm scraping shorter rocks I might, instead, use more teeth spaced closer together to act like a conventional rockbucket teeth where the dirt can fall between the teeth and I can tip the bucket up to deposit the rocks in the FEL bucket.

Anyway, hopefully you get the crude idea (sorry about the lousy drawing).

I'd appreciate any comments, suggestions, or indications I'm certifiably nuts.

Bob