kiotiken

Veteran Member

I know there have been a few threads already, but I have a few hydraulic questions. This will be my first hydraulic project and I really have no idea what I'm doing so I'm looking for guidance and validation that my creation wont simply self destruct.

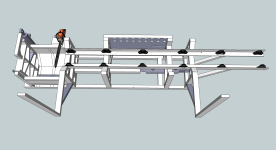

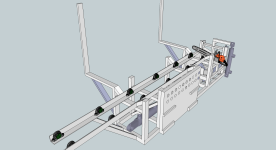

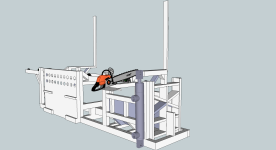

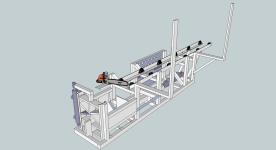

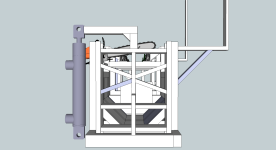

I'm planning a processor that will use my Stihl 361 to cut, so that part isn't an issue. I am planning to build a splitter, a feeder and an conveyor. My plan is to use old tires for the feeder, cut the side walls off and join them together. That part of the feeder will be powered by one hydraulic motor and I'm planning on using a second identical motor for a top clamping roller. I plan on constructing the conveyor from scrap ski-doo tracks and if I can't find those, tires again joined together with angle iron.

I am planning to use 2 15hp engines for power. The first engine will be dedicated to the splitter and the second will run the conveyor and feeder motors.

Splitter: I'm planning to use the 2 stage, 28/7 GPM log splitter pump from the Surplus Center. The requirement is 16hp, but 15 will have to do. 28 GPM DYNAMIC 2-STAGE PUMP

The rest: I was planning on using a multi section pump with one pump powering the conveyor and the second powering the feed motors and ax height cylinder. Here is the one I was looking at: 1.29/0.69 cu in CASAPPA PLP20.20/20.11 DOUBLE PUMP

Some questions:

1) Can I use one reservoir with tees to feed both pumps or do I need to have two reservoirs?

2) Most of the multi section pumps seem to have a max speed of 3000 RPM while the standard for a gas engine is 3600 RPM. I want to directly connect the pump to the engine, how do you resolve this, is there another pump I should be looking at?

3) The pressure from the multi section pumps if far higher than the max cont. pressure listed on any of the hydraulic motors. Do I use a relief valve set at the proper operating pressure or is there a better solution?

4) I would like one circuit to run the two feeder motors (belt and upper roller). Can I use a tee to feed the two motors, returning to another tee?

5) I would like the splitter to have an auto cycle function. Preferably, I'd like to simply hit a button, but that might be cost prohibitive. What is the best way to achieve an auto cycle?

6) I need help sizing and selecting motors for the conveyor and feeders.

I probably have a bunch of other questions I'm forgetting at the moment but any help with these would be very much appreciated.

I'm planning a processor that will use my Stihl 361 to cut, so that part isn't an issue. I am planning to build a splitter, a feeder and an conveyor. My plan is to use old tires for the feeder, cut the side walls off and join them together. That part of the feeder will be powered by one hydraulic motor and I'm planning on using a second identical motor for a top clamping roller. I plan on constructing the conveyor from scrap ski-doo tracks and if I can't find those, tires again joined together with angle iron.

I am planning to use 2 15hp engines for power. The first engine will be dedicated to the splitter and the second will run the conveyor and feeder motors.

Splitter: I'm planning to use the 2 stage, 28/7 GPM log splitter pump from the Surplus Center. The requirement is 16hp, but 15 will have to do. 28 GPM DYNAMIC 2-STAGE PUMP

The rest: I was planning on using a multi section pump with one pump powering the conveyor and the second powering the feed motors and ax height cylinder. Here is the one I was looking at: 1.29/0.69 cu in CASAPPA PLP20.20/20.11 DOUBLE PUMP

Some questions:

1) Can I use one reservoir with tees to feed both pumps or do I need to have two reservoirs?

2) Most of the multi section pumps seem to have a max speed of 3000 RPM while the standard for a gas engine is 3600 RPM. I want to directly connect the pump to the engine, how do you resolve this, is there another pump I should be looking at?

3) The pressure from the multi section pumps if far higher than the max cont. pressure listed on any of the hydraulic motors. Do I use a relief valve set at the proper operating pressure or is there a better solution?

4) I would like one circuit to run the two feeder motors (belt and upper roller). Can I use a tee to feed the two motors, returning to another tee?

5) I would like the splitter to have an auto cycle function. Preferably, I'd like to simply hit a button, but that might be cost prohibitive. What is the best way to achieve an auto cycle?

6) I need help sizing and selecting motors for the conveyor and feeders.

I probably have a bunch of other questions I'm forgetting at the moment but any help with these would be very much appreciated.