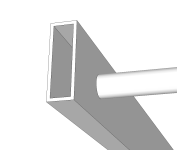

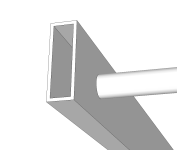

I am tee-welding 1" solid bar to a 1x2" tube 11ga. There are about 30 of these joints to do, and I was tempted to cut a 1" hole in the tube and recess everything inside before the weld, but not looking forward to boring 30 holes. Want to test with MIG and/or flux-core.

So any ideas on the best way to section test this (weld, then cut and inspect) with nothing but a chop saw?

If I can weld the butts and be satisfied with outcome, I'll do it. Otherwise I'll probably drill out the tube on one side and put the bar inside, then weld to hold it and seal it.

These are monkey bars. Literally kid's stuff. But that also means I want them to hold up.

So any ideas on the best way to section test this (weld, then cut and inspect) with nothing but a chop saw?

If I can weld the butts and be satisfied with outcome, I'll do it. Otherwise I'll probably drill out the tube on one side and put the bar inside, then weld to hold it and seal it.

These are monkey bars. Literally kid's stuff. But that also means I want them to hold up.