Oasis

Member

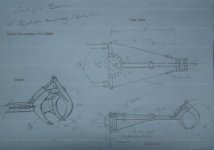

Rained out_ had time to sketch some ideas.

I would appreciate your thoughts on this design.

Purpose:

This FEL attachment is for handling heavy rock. I often have to carefully place a few thousand pounds of rock per day, many weigh a couple hundred pounds (see photos). I also load rock onto a flat bed trailer at a local quarry. I currently use a FEL and tongs...

Design features:

Boom reaches about 8 feet for loading/placing individual rocks within typical reach requirements.

Boom length can be shortened for transport of tractor combo and for use in cramped workspace situations. Length can also be shortened for carrying maximum size rock.

Boom swing allows for some fine tune rock placement, and for situations where the tractor can only park parallel to the work. This allows rock (within weight limits) to be swung left or right of the tractor. The chain and holes/pin feature allows boom swing without risk of runaway. This could be important when working on non-level ground. Example: place pin as stop, release holding chain, swing boom to stop, reattach chain, place keeper pin.

Grapple grab is preferred front to back using single thumb to lessen interference with neighboring rock.

The grapple would operate on a solenoid valve hooked into the curl hydraulics using a momentary joystick switch. (JD 790/70 FEL)

This attachment could obviously be used for other things but my primary goal is for the type pf rockwork seen in the photos.

Spec suggestions, flaws, improvements, other designs?

I was considering some type of remote release that I could use while standing at the grapple.

Thanks again to all of you contributors out there, especially for your grapple threads.

I would appreciate your thoughts on this design.

Purpose:

This FEL attachment is for handling heavy rock. I often have to carefully place a few thousand pounds of rock per day, many weigh a couple hundred pounds (see photos). I also load rock onto a flat bed trailer at a local quarry. I currently use a FEL and tongs...

Design features:

Boom reaches about 8 feet for loading/placing individual rocks within typical reach requirements.

Boom length can be shortened for transport of tractor combo and for use in cramped workspace situations. Length can also be shortened for carrying maximum size rock.

Boom swing allows for some fine tune rock placement, and for situations where the tractor can only park parallel to the work. This allows rock (within weight limits) to be swung left or right of the tractor. The chain and holes/pin feature allows boom swing without risk of runaway. This could be important when working on non-level ground. Example: place pin as stop, release holding chain, swing boom to stop, reattach chain, place keeper pin.

Grapple grab is preferred front to back using single thumb to lessen interference with neighboring rock.

The grapple would operate on a solenoid valve hooked into the curl hydraulics using a momentary joystick switch. (JD 790/70 FEL)

This attachment could obviously be used for other things but my primary goal is for the type pf rockwork seen in the photos.

Spec suggestions, flaws, improvements, other designs?

I was considering some type of remote release that I could use while standing at the grapple.

Thanks again to all of you contributors out there, especially for your grapple threads.