moojamboo

Bronze Member

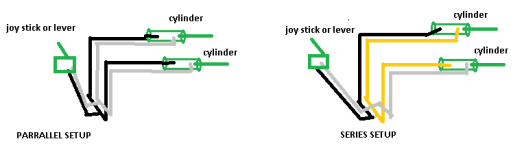

I have installed my two bucket cylinders after being repacked. I have tried extending and retracting the cylinders without the bucket. The cylinders extend at different rates. The one which is first in the series will extend faster than the other. Once the first cylinder is fully extended the second cylinder extends faster. same occurs when retracted. There is about a 2 second time differential between the first cylinder being fully retracted/extended and the second cylinder. The hydraulic level seems good.

Is the difference in rates normal or should I be concerned? Any advice welcome.

Is the difference in rates normal or should I be concerned? Any advice welcome.