RichardDLee

Bronze Member

Hello,

I have just bought a second hand Yanmar RS 1303 tiller in pretty good condition. The problem is that the PTO shaft is too long.

Now it's not a regular new type of shaft which is nice and easy to shorten, it's a solid cylinder of metal splined for the last 6 inches and just plain cylinder behind that.

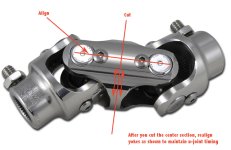

My question is...... Can I cut out the non splined cylinder section and reweld the splined section back onto the shaft?

I will only be tilling for a few hours a month, not constant or daily use.

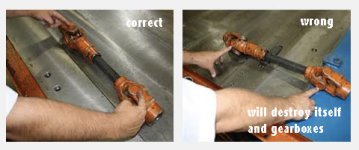

Will it be impossible to get straight? Will I just ruin bearings?

Will it be strong enough to hold?

I bought a new PTO shaft but I realised that the 2 yokes length was the full distance between tractor and tiller, this tiller was meant for my tractor so why is it not easy to get the correct shaft?

The distance between the 2 bolt cut outs on each splined when mounted is only 420mm, am I being daft?

Somebody please help.....

Thanks.

I have just bought a second hand Yanmar RS 1303 tiller in pretty good condition. The problem is that the PTO shaft is too long.

Now it's not a regular new type of shaft which is nice and easy to shorten, it's a solid cylinder of metal splined for the last 6 inches and just plain cylinder behind that.

My question is...... Can I cut out the non splined cylinder section and reweld the splined section back onto the shaft?

I will only be tilling for a few hours a month, not constant or daily use.

Will it be impossible to get straight? Will I just ruin bearings?

Will it be strong enough to hold?

I bought a new PTO shaft but I realised that the 2 yokes length was the full distance between tractor and tiller, this tiller was meant for my tractor so why is it not easy to get the correct shaft?

The distance between the 2 bolt cut outs on each splined when mounted is only 420mm, am I being daft?

Somebody please help.....

Thanks.