lslarry86

New member

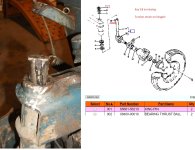

Mowing roadsides yesterday, the left knuckle of my B5200 snapped off, where the long drag link joins the knuckle. I was about a half mile from the house, and couldn't see how to tow it with no steering. So I made this rig to get home. Worked ok, despite almost a full turn of lash in the linkage. But now I can't get the knuckle off. The exploded diagrams look like I should be able to loosen the pinch bolt and lift the knuckle right off, theoretically at least. I have watched the Pitman arm videos on youtube, so I know it can be tough. But this part looks like somebody peened the top of the shaft, or maybe even welded it. Do people do that?

Does this look like a weld to the assembled experts? Should I try to grind it? (click the thumbnail for 400x600 pixel version, look where the knuckle joins the vertical shaft)

Thanks,

Larry