LD1

Epic Contributor

Bear with me, this will probably be a longer post than I intend.

The purpose of this exercise was to find the CG of my tractor in various configurations. So I broke out one of my college books on how to find the CG by raising one side up a given distance and seeing how much weight was transferred to the other axle. The higher you can go, the more accurate, which is part of my issue, since I can only go 12" comfortably. And any raising the rear any higher would cause me to have to elevate the FEL more giving another false reading.

So anyway, Following the formulas, I kept getting a really low CG height. Then it dawned on me that the formula works for cars cause the tires are the same diameter. So after browsing the net, I found a good calculator that will account for the different sizes. CG Height Calculator | Automotive Brake System Calculator | BRAKE POWER

So after plugging in all of the numbers:

Tractor, with FEL raised to 9.5", and bushhog with no weight on tailwheel: COG height was 22.3"

Tractor, with FEL raised to 9.5", and bushhog OFF, nothing else on 3PH...: COG height was 21.5"

Bare tractor, nothing on either end..................................................... : COG height was 23.8"

So not really much change in height. One thing that I dont understand....Having the bushhog low, gave a higher CG than with it off?

Now I know my weight measurements arent spot on. I was using a bottle jack with a 1000psi pressure gauge that has 20psi graduations. And the size of the jack, each PSI = 4lbs. But all three scenarios added 20psi to the front when raised, which is 80lbs. But I would say with the gauge, that could be a +/- 20lbs

But in any case, the CoG of all thee are close enough not to worry about, so going forward to CoG F/R location:

I want to calculate the static tipping angle of the tractor. The way I am doing that, which I believe is correct, seems to give awfully high numbers. But I know its static numbers and dont count for the dynamics of actually moving.

My rear tire width is identical to the wheelbase. 63.3". So using the stability triangle, we get an isosceles triangle with a 63.3" base and a 63.3" height. That couldnt have worked out any better, cause for each inch the height is shortened, the based is shortened by the same amount.

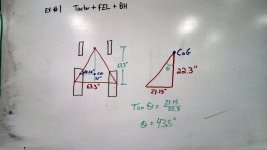

So.....Example 1 With FEL and Hog attached, the CoG is 21" forward of the rear axle and 22.3" high. Given the stability triangle, the tractor would have to be on an angle such that the COG would have to move 21.15" to the left or right to go outside the triangle. (not really the COG moving, but imagine a plumb bob attached at the COG point, and place the tractor on an angle. That plumb bob would have to move 21.15" at ground level) That angle would need to be 44.1

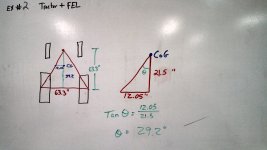

In example 2, with tractor and FEL, the CoG is 39.2" forward of the rear axle and 21.5" high. Given that it is much closer to the front axle, the stability triangle is much narrower up there and would only need the COG to move 12.05" before tip-over. That angle would be 29.24 degrees

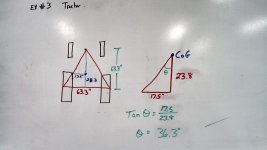

Example 3 with bare tractor, the CoG is located 28.3" forward of the rear axle. About half way between Examples 1 and 2. And with a height of 23.8" A static tipping angle would be 36.34 degrees.

So here is the question: am I figuring the stability triangle and static tipping angle right? They seem like pretty high angles. I know at 22 degrees with the FEL and bushhog feels pretty uneasy, but according to this, I would need double in a static condition to upset. I know that at 22 degrees and wet grass, some sliding occurs. I know this dont count for the dynamics of moving, or me on the seat, or inertia of dropping a tire in a small hole.

All input is welcome. I know there are some pretty well versed members here in regards to the physics of this and math in general. So lets here it.

Edit: I also think it is important to note, that if my figuring is correct, while the FEL does lower the CoG, that dont mean it is more stable on a side slope.

The purpose of this exercise was to find the CG of my tractor in various configurations. So I broke out one of my college books on how to find the CG by raising one side up a given distance and seeing how much weight was transferred to the other axle. The higher you can go, the more accurate, which is part of my issue, since I can only go 12" comfortably. And any raising the rear any higher would cause me to have to elevate the FEL more giving another false reading.

So anyway, Following the formulas, I kept getting a really low CG height. Then it dawned on me that the formula works for cars cause the tires are the same diameter. So after browsing the net, I found a good calculator that will account for the different sizes. CG Height Calculator | Automotive Brake System Calculator | BRAKE POWER

So after plugging in all of the numbers:

Tractor, with FEL raised to 9.5", and bushhog with no weight on tailwheel: COG height was 22.3"

Tractor, with FEL raised to 9.5", and bushhog OFF, nothing else on 3PH...: COG height was 21.5"

Bare tractor, nothing on either end..................................................... : COG height was 23.8"

So not really much change in height. One thing that I dont understand....Having the bushhog low, gave a higher CG than with it off?

Now I know my weight measurements arent spot on. I was using a bottle jack with a 1000psi pressure gauge that has 20psi graduations. And the size of the jack, each PSI = 4lbs. But all three scenarios added 20psi to the front when raised, which is 80lbs. But I would say with the gauge, that could be a +/- 20lbs

But in any case, the CoG of all thee are close enough not to worry about, so going forward to CoG F/R location:

I want to calculate the static tipping angle of the tractor. The way I am doing that, which I believe is correct, seems to give awfully high numbers. But I know its static numbers and dont count for the dynamics of actually moving.

My rear tire width is identical to the wheelbase. 63.3". So using the stability triangle, we get an isosceles triangle with a 63.3" base and a 63.3" height. That couldnt have worked out any better, cause for each inch the height is shortened, the based is shortened by the same amount.

So.....Example 1 With FEL and Hog attached, the CoG is 21" forward of the rear axle and 22.3" high. Given the stability triangle, the tractor would have to be on an angle such that the COG would have to move 21.15" to the left or right to go outside the triangle. (not really the COG moving, but imagine a plumb bob attached at the COG point, and place the tractor on an angle. That plumb bob would have to move 21.15" at ground level) That angle would need to be 44.1

In example 2, with tractor and FEL, the CoG is 39.2" forward of the rear axle and 21.5" high. Given that it is much closer to the front axle, the stability triangle is much narrower up there and would only need the COG to move 12.05" before tip-over. That angle would be 29.24 degrees

Example 3 with bare tractor, the CoG is located 28.3" forward of the rear axle. About half way between Examples 1 and 2. And with a height of 23.8" A static tipping angle would be 36.34 degrees.

So here is the question: am I figuring the stability triangle and static tipping angle right? They seem like pretty high angles. I know at 22 degrees with the FEL and bushhog feels pretty uneasy, but according to this, I would need double in a static condition to upset. I know that at 22 degrees and wet grass, some sliding occurs. I know this dont count for the dynamics of moving, or me on the seat, or inertia of dropping a tire in a small hole.

All input is welcome. I know there are some pretty well versed members here in regards to the physics of this and math in general. So lets here it.

Edit: I also think it is important to note, that if my figuring is correct, while the FEL does lower the CoG, that dont mean it is more stable on a side slope.