Spencer

Veteran Member

- Joined

- Jan 2, 2002

- Messages

- 1,267

- Location

- Western Michigan

- Tractor

- NH TC33D w/R4 Tires, Rear Remote, Hydraulic Toplink, 2 Auxiliary Work Lights, 7308 Loader w/Kasco Uni-Hitch (Quick Tach)

This has been touched on before but I wanted a central discussion on the topic. I set the first five posts of my pole barn last night and I want to get the holes filled as soon as possible. Some of you have said to use no concrete at all around the posts because it will make them rot sooner. Some of you have said to pour a 6" or so collar of concrete around the base and then back fill the rest of the hole with dirt or stone.

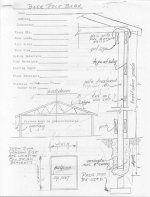

I submitted my pole barn plans to the township which stated that I would be setting the posts on concrete cookies and then pouring concrete around the posts. I did not state how high I would pour the concrete around the posts or the diameter of the cookie to be used. The only addition/correction the that building inspector who reviewed my plans made was to state that the cookie had to be a minimum of 14" in diameter. He did not state anything about the concrete around the posts. Now in reviewing all the documents I got from the township I found a sheet that they gave me which is a cross section of one wall of a pole barn (see attachment). They make you fill this out and submit it with your plans. As you can see on this sheet it shows concrete filled all the way up to grade and it says "concrete min. 4" cover".

Before I read on TBN about the possible problems with concrete around posts I was planning on filling them up fairly high. I have a very high water table here for half of the year and thought that concrete against the posts was better than water. After reading about the subject on TBN I was convinced to just pour a 6" or 8" collar of concrete around the posts and back fill them with sand. Now it looks as if I may have to fill them all the way up. I will try to get clarification from my township today but I wanted to hear your opinions again of the subject in case the inspector leaves the decision up to me.

Please post any links with solid information on this subject along with your opinions if you can. I am really interested in seeing some evidence about the concrete making the posts rot sooner or causing problems with heaving from frost.

I submitted my pole barn plans to the township which stated that I would be setting the posts on concrete cookies and then pouring concrete around the posts. I did not state how high I would pour the concrete around the posts or the diameter of the cookie to be used. The only addition/correction the that building inspector who reviewed my plans made was to state that the cookie had to be a minimum of 14" in diameter. He did not state anything about the concrete around the posts. Now in reviewing all the documents I got from the township I found a sheet that they gave me which is a cross section of one wall of a pole barn (see attachment). They make you fill this out and submit it with your plans. As you can see on this sheet it shows concrete filled all the way up to grade and it says "concrete min. 4" cover".

Before I read on TBN about the possible problems with concrete around posts I was planning on filling them up fairly high. I have a very high water table here for half of the year and thought that concrete against the posts was better than water. After reading about the subject on TBN I was convinced to just pour a 6" or 8" collar of concrete around the posts and back fill them with sand. Now it looks as if I may have to fill them all the way up. I will try to get clarification from my township today but I wanted to hear your opinions again of the subject in case the inspector leaves the decision up to me.

Please post any links with solid information on this subject along with your opinions if you can. I am really interested in seeing some evidence about the concrete making the posts rot sooner or causing problems with heaving from frost.