HLHP

New member

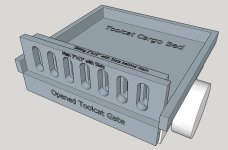

I have been thinking about a DIY sander on the back of our Toolcat. This would be for pure sand, probably somewhat wet. We are not allow to put any salt in our mix. This idea is to make the bed into a big "salt shaker" or actually a sand shaker in this case.

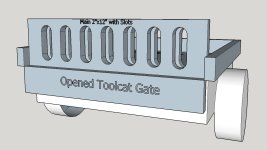

The main idea is to cut a 2"x12" (or larger) that would sit inside the bed and parallel to the rear gate. The board would be just in front of the gate. The 2"x12" would have large slots or holes in it that would disperse sand when the Toolcat's rear gate is opened and the hydraulic lift on the bed is raised. Jiggling the bed during lift and the driving would act a bit like a vibrator. I think that the bed lifts to 45 degrees and sanding uphill on our steep roads would help. We have roads that are 8% grade or more in our mountain community.

Has anyone ever tried this? Do you think this would work? I'm thinking 4 inch or larger slots/holes. The benefit of this approach for our Toolcat is that it would still fit in our very tight garage. A typical sander hanging off the back would not fit. Another benefit is that it would take advantage of the Toolcat's 1-ton hydraulic bed. With the right size holes/slots, I'm hopeful that the partially wet sand would come out, especially when going uphill.

One issue would probably be adjusting for the level of moisture in the sand. A similarly cut but shorter length 2"x12" directly against the main 2"x12" might allow us to adjust the width of the slots as needed in order to vary the size of the holes by sliding the shorter 2"x12" right or left to effectively widen or decrease the size of the slots. Boards that extend upward on the sides of the bed might also be needed to keep the sand from spilling out. If it works, we could add a plywood top for drier sand when plowing during a storm. If it fails, the cost would probably be less than $100.

Has anyone ever done this and made it work?

Here are a couple of diagrams that may help:

The main idea is to cut a 2"x12" (or larger) that would sit inside the bed and parallel to the rear gate. The board would be just in front of the gate. The 2"x12" would have large slots or holes in it that would disperse sand when the Toolcat's rear gate is opened and the hydraulic lift on the bed is raised. Jiggling the bed during lift and the driving would act a bit like a vibrator. I think that the bed lifts to 45 degrees and sanding uphill on our steep roads would help. We have roads that are 8% grade or more in our mountain community.

Has anyone ever tried this? Do you think this would work? I'm thinking 4 inch or larger slots/holes. The benefit of this approach for our Toolcat is that it would still fit in our very tight garage. A typical sander hanging off the back would not fit. Another benefit is that it would take advantage of the Toolcat's 1-ton hydraulic bed. With the right size holes/slots, I'm hopeful that the partially wet sand would come out, especially when going uphill.

One issue would probably be adjusting for the level of moisture in the sand. A similarly cut but shorter length 2"x12" directly against the main 2"x12" might allow us to adjust the width of the slots as needed in order to vary the size of the holes by sliding the shorter 2"x12" right or left to effectively widen or decrease the size of the slots. Boards that extend upward on the sides of the bed might also be needed to keep the sand from spilling out. If it works, we could add a plywood top for drier sand when plowing during a storm. If it fails, the cost would probably be less than $100.

Has anyone ever done this and made it work?

Here are a couple of diagrams that may help:

Last edited: