orezok

Elite Member

I have a British made root-tiller (Blecavator) that uses a Eurocardan slip clutch. This clutch is different as it uses Belleville springs in lieu of coil springs. The springs are non adjustable as they are diaphragm springs. Both springs are cracked and the clutch is slipping.

Replacement springs are about $100 and new clutch discs are $70. For just a little more money I can buy a new style clutch.

The issue is that I only use this tiller once or twice a year and that doesn't justify the cost of a new clutch.

Any thoughts on welding the cracks back together? A C-clamp pulls the crack together and reestablishes a more curved profile to the spring which would add more pressure. They are about 0.115" thick. If I welded it and it failed again it would be no loss other than my time.

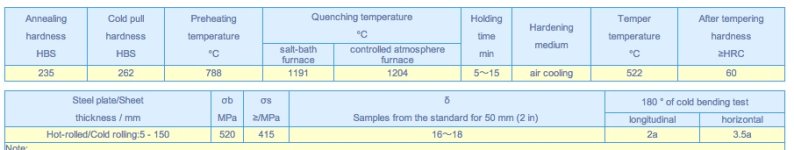

The steel in the springs is most likely 50CrV4 which has .5 C, .4 SI, 1.0 MN, 1.0 CR AND .2V

So the questions are:

V out or just butt

Tig or Mig

309 or mild steel

Replacement springs are about $100 and new clutch discs are $70. For just a little more money I can buy a new style clutch.

The issue is that I only use this tiller once or twice a year and that doesn't justify the cost of a new clutch.

Any thoughts on welding the cracks back together? A C-clamp pulls the crack together and reestablishes a more curved profile to the spring which would add more pressure. They are about 0.115" thick. If I welded it and it failed again it would be no loss other than my time.

The steel in the springs is most likely 50CrV4 which has .5 C, .4 SI, 1.0 MN, 1.0 CR AND .2V

So the questions are:

V out or just butt

Tig or Mig

309 or mild steel