petes

Silver Member

- Joined

- Dec 26, 2009

- Messages

- 108

- Location

- Bellingham, Washington

- Tractor

- Kubota B8200 (21hp) , IH B275 (28hp), JD 1830 (68hp)

We bought 40 used stall mats(100-ish lbs each and awkward as heck) on Saturday, "un-in-stalled", moved, loaded and unloaded them on my trailer. I decided I don't want to move them by hand again from where they are stacked... That, and a couple other ideas/project (paletized power-aerated composting bins, carryall, brush piles to be moved, etc.) justified prioritizing a pallet fork build next.

Design goals are:

FEL and 3pt mountable

48" long

Reasonably light weight (Kubota B7100, 500lb FEL capacity), but strong enough.

Adjustable width

Down-force capable (when on FEL)

Multi-purpose FEL/3pt frame (future hay sweep, bale pickup, snowplow, grapple?)

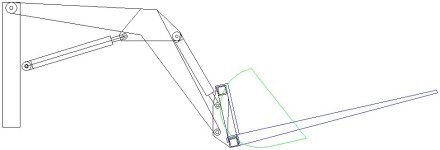

The frame will be 2x2 dual rail, 48" wide with FEL pin and 3pt pin ears. I may make a pin quick-attach while I'm at it to make switching from bucket to forks easier, but don't really want the additional ~3" space and weight which will both decrease already meager lift capacity.

Forks will be removable from the frame. They'll "drop down" over the top and bottom rails and either clamp or have a jamb-cam against the top rail that forces them down/holds them in place. I've got some figuring yet to do on that...

Use as many materials I already have or can get cheaply from the scrapyard

I started construction Sunday afternoon. Progress so far:

Forks cut from a 3"x5"x0.25" box tube. 3" wide 48" long, 2-1/2" at the big end tapered to 5/8 at the small end. (Love that plasma cutter!)

Notched to to fit over 2x2 frame rail

1.5 x 1.5 x 7" angle welded in the notch to reinforce the "big" end end, and will keep the forks aligned perpendicular to the frame.

Boxed with 0.187 cut from plate. (Welding out the boxing tested the dutycycle limit on my MIG... DOH!)

Then it was time for supper...

Design goals are:

FEL and 3pt mountable

48" long

Reasonably light weight (Kubota B7100, 500lb FEL capacity), but strong enough.

Adjustable width

Down-force capable (when on FEL)

Multi-purpose FEL/3pt frame (future hay sweep, bale pickup, snowplow, grapple?)

The frame will be 2x2 dual rail, 48" wide with FEL pin and 3pt pin ears. I may make a pin quick-attach while I'm at it to make switching from bucket to forks easier, but don't really want the additional ~3" space and weight which will both decrease already meager lift capacity.

Forks will be removable from the frame. They'll "drop down" over the top and bottom rails and either clamp or have a jamb-cam against the top rail that forces them down/holds them in place. I've got some figuring yet to do on that...

Use as many materials I already have or can get cheaply from the scrapyard

I started construction Sunday afternoon. Progress so far:

Forks cut from a 3"x5"x0.25" box tube. 3" wide 48" long, 2-1/2" at the big end tapered to 5/8 at the small end. (Love that plasma cutter!)

Notched to to fit over 2x2 frame rail

1.5 x 1.5 x 7" angle welded in the notch to reinforce the "big" end end, and will keep the forks aligned perpendicular to the frame.

Boxed with 0.187 cut from plate. (Welding out the boxing tested the dutycycle limit on my MIG... DOH!)

Then it was time for supper...