patrick_g

Elite Member

This post does involve tractor work (but not the central theme) so let me know if I shouldn't ask it here.

I will be building a new fence. It will have the hollow vinyl posts and vinyl slats that are supposed to be good for holding in livestock. I have a 3PH mounted PTO driven cement mixer and a 3PH mounted PHD. Unless someone gives me good reasons to do otherwise I am thinking I will use the PHD to auger 12 inch diameter holes. I also have a 9 inch auger but I need to be sure I can place the posts DEAD ON layout so the extra "wiggle" room from the larger hole may be a good idea even though it takes more materials and effort to fill the hole.

I am planning to fill the hole with a mixture of limestone "screenings" (small gravel down to dust and everything in between) and Portland cement. I may add some larger gravel if that meets with significant approval here on TBN.

I do not intend to add water to the mix but will use the mixer to mix the dry ingredients, fill tamp, fill tamp, etc. and then let ground moisture cure the cement over time.

I will fill the hollow posts from the bottom to the height of the first plank with the mixture. This should help prevent the post from collapsing at ground level from a good side load (say a 1000 pounder leans into it.) Does anyone think I should use a different recipe for the "grout" I put inside the post? Even filling a post with sand makes it stronger as it prevents premature collapse and easy bending.

I can "drill" all the holes and then change implements to the mixer to set the posts. If there is sufficient commentary regarding adding water I would consider adding water to the holes in advance and pouring some on top afterwards but I really don't want to have to transport enough water to mix regular concrete and deal with the wet mud. I haven't measured the proposed fence line yet but estimate a bit over a quarter mile. This is a DIY project with some help from an experienced friend.

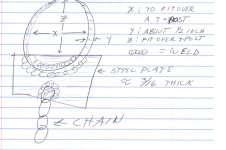

To help ensure that the fence does indeed contain stock I will drill holes in the vinyl plastic posts and thread a hot wire through it attached to a powerful fence charger. That way when they try to stick their head through to access the GREENER grass on the other side they will get a negative reinforcement. I had a custom HD fencer built that is supposed to be good for bulls and beefalo and runs on 12 volts. I will install solar electric panels and a deep cycle battery to power the charger.

Any comments are welcome. If this post belongs somewhere else, let me know.

Pat

I will be building a new fence. It will have the hollow vinyl posts and vinyl slats that are supposed to be good for holding in livestock. I have a 3PH mounted PTO driven cement mixer and a 3PH mounted PHD. Unless someone gives me good reasons to do otherwise I am thinking I will use the PHD to auger 12 inch diameter holes. I also have a 9 inch auger but I need to be sure I can place the posts DEAD ON layout so the extra "wiggle" room from the larger hole may be a good idea even though it takes more materials and effort to fill the hole.

I am planning to fill the hole with a mixture of limestone "screenings" (small gravel down to dust and everything in between) and Portland cement. I may add some larger gravel if that meets with significant approval here on TBN.

I do not intend to add water to the mix but will use the mixer to mix the dry ingredients, fill tamp, fill tamp, etc. and then let ground moisture cure the cement over time.

I will fill the hollow posts from the bottom to the height of the first plank with the mixture. This should help prevent the post from collapsing at ground level from a good side load (say a 1000 pounder leans into it.) Does anyone think I should use a different recipe for the "grout" I put inside the post? Even filling a post with sand makes it stronger as it prevents premature collapse and easy bending.

I can "drill" all the holes and then change implements to the mixer to set the posts. If there is sufficient commentary regarding adding water I would consider adding water to the holes in advance and pouring some on top afterwards but I really don't want to have to transport enough water to mix regular concrete and deal with the wet mud. I haven't measured the proposed fence line yet but estimate a bit over a quarter mile. This is a DIY project with some help from an experienced friend.

To help ensure that the fence does indeed contain stock I will drill holes in the vinyl plastic posts and thread a hot wire through it attached to a powerful fence charger. That way when they try to stick their head through to access the GREENER grass on the other side they will get a negative reinforcement. I had a custom HD fencer built that is supposed to be good for bulls and beefalo and runs on 12 volts. I will install solar electric panels and a deep cycle battery to power the charger.

Any comments are welcome. If this post belongs somewhere else, let me know.

Pat