farm boy00

Veteran Member

- Joined

- Jul 17, 2014

- Messages

- 1,297

- Location

- Howard City, MI

- Tractor

- John Deere M&MT, Case 1030 comfort king, Sears ST16, Craftsmen 6000, homemade articulation mini-loader

First thing. Not a big tractor or even a sub compact.

Just bought this tractor a week ago or so. Have been having problems where the guy welded the tractor loader. It is where the loader drops down. This tractor was a custom from a trencher. Looks to be all good designs, but was only made for moving some soil around or some mulch. Why we broke the loader was because the first morning we had the tractor we used it to dig a septic pipe in wet clay ground.

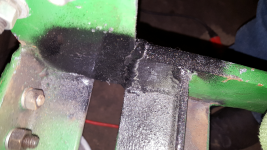

This is after grinding welds down and pulling it back together.

Used chains and chain binders to pull it together. Then used a bottle jack to push it back out from getting twisted (kept using it for a week cleaning a barn and digging out a septic pipe)

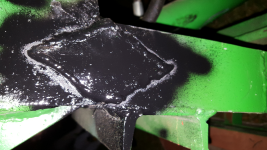

Fish plates cut and ready to weld

Dinner break. Little sister watching mickey mouse and caught my dad watching

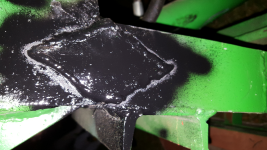

Went out and had him weld it. Didn't get no pictures before adding fish plates

View attachment 447332

And grinded out a section where my lift cylinder was hitting

Test. Front end was lifted about 6-12 inches off the ground

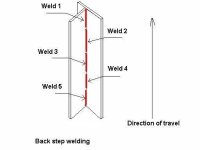

What you guys think? ? Anything you would have done different? ? Actually tought my dad new thing about fish plates from this forum. He didn't know they were supposed to be like a Dimond.

Just bought this tractor a week ago or so. Have been having problems where the guy welded the tractor loader. It is where the loader drops down. This tractor was a custom from a trencher. Looks to be all good designs, but was only made for moving some soil around or some mulch. Why we broke the loader was because the first morning we had the tractor we used it to dig a septic pipe in wet clay ground.

This is after grinding welds down and pulling it back together.

Used chains and chain binders to pull it together. Then used a bottle jack to push it back out from getting twisted (kept using it for a week cleaning a barn and digging out a septic pipe)

Fish plates cut and ready to weld

Dinner break. Little sister watching mickey mouse and caught my dad watching

Went out and had him weld it. Didn't get no pictures before adding fish plates

View attachment 447332

And grinded out a section where my lift cylinder was hitting

Test. Front end was lifted about 6-12 inches off the ground

What you guys think? ? Anything you would have done different? ? Actually tought my dad new thing about fish plates from this forum. He didn't know they were supposed to be like a Dimond.