toukow

Silver Member

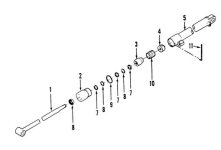

I'm about to embark on rebuilding the tilt cylinder on a Ford 770 loader that is on my Ford 1700 tractor. At the link below the gentleman encountered issues, which hopefully I will be able to avoid. I'm lucky in that the original poster scanned the page which I assume will be similar for the tilt cylinder.

My main question is this- do loaders have their own repair manuals? I have the 770 owners manual which does not discuss repair, but a search of the number in the lower right of the page shown at the link turned up nothing. Thanks.

http://www.tractorbynet.com/forums/hydraulics/203164-loader-bucket-cylinder-repair-help.html

My main question is this- do loaders have their own repair manuals? I have the 770 owners manual which does not discuss repair, but a search of the number in the lower right of the page shown at the link turned up nothing. Thanks.

http://www.tractorbynet.com/forums/hydraulics/203164-loader-bucket-cylinder-repair-help.html