SacandagaBrad

Platinum Member

In an earlier post I described an instantaneous stall due to a shear bolt not breaking on a Woods SS52 snow blower blowing snow....

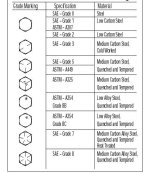

Well, I feeling better and got out to check the factory installed shear bolt on the drive shaft. It is a Gr 8 /forums/images/graemlins/mad.gif I picked up a handfull of Gr 2 and Gr 5 to try.

I encourage anyone with a new Woods snow blower to check the drive shaft shear bolt to make sure it is not a Gr 8. Easy enough to do without removing the bolt, you can see the head of the bolt clearly. If you've got 6 hash marks on the head, it's a Gr 8! Get it out of there. A TC24 at 2500 RPMs and little snow load could not shear it. That's asking for trouble IMO.

I just called my dealer to alert him to the problem, he was surprised and will check all new ones going out the door from now on. Seemed appreciative of the notice.

I would be interested to hear the results of your inspections. As pointed out by Rick in the earlier post, Woods indicated to him that the Gr8 spec in the manual was an error. Apparently they get their drive shafts from an outside source, who probably just used Woods spec without questioning it.

Anyway, if this saves anyone some serious damage to your tractror, it was worth the post.

Brad

Well, I feeling better and got out to check the factory installed shear bolt on the drive shaft. It is a Gr 8 /forums/images/graemlins/mad.gif I picked up a handfull of Gr 2 and Gr 5 to try.

I encourage anyone with a new Woods snow blower to check the drive shaft shear bolt to make sure it is not a Gr 8. Easy enough to do without removing the bolt, you can see the head of the bolt clearly. If you've got 6 hash marks on the head, it's a Gr 8! Get it out of there. A TC24 at 2500 RPMs and little snow load could not shear it. That's asking for trouble IMO.

I just called my dealer to alert him to the problem, he was surprised and will check all new ones going out the door from now on. Seemed appreciative of the notice.

I would be interested to hear the results of your inspections. As pointed out by Rick in the earlier post, Woods indicated to him that the Gr8 spec in the manual was an error. Apparently they get their drive shafts from an outside source, who probably just used Woods spec without questioning it.

Anyway, if this saves anyone some serious damage to your tractror, it was worth the post.

Brad