jpover

Member

Friends,

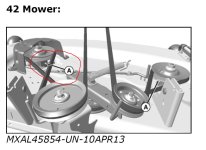

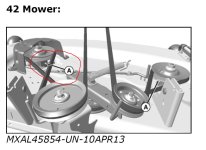

I have an X304 with a missing grease zerk (see pic/diagram with red circle). I purchased a replacement grease zerk from JD but it's threaded and does not seat.

So, I called JD parts (local) and found out:

1) the spindle bearing is sealed so the zerk doesn't serve much purpose other than "customers wanted a zerk in that location"

2) the factory zerk is a press-in so a standard threaded won't work. Funny, when I purchased it I told them which zerk I needed for that mower and that's what they sold me.

As such, any recommendation on sizing for a self threading zerk or perhaps tapping it myself? I'm hesitant to tap it as I don't want to damage the bearing seal.

If you had this issue, did you resolve it? I'll likely just leave as is since it sounds like a non-issue but wanted some feedback.

Thanks!

I have an X304 with a missing grease zerk (see pic/diagram with red circle). I purchased a replacement grease zerk from JD but it's threaded and does not seat.

So, I called JD parts (local) and found out:

1) the spindle bearing is sealed so the zerk doesn't serve much purpose other than "customers wanted a zerk in that location"

2) the factory zerk is a press-in so a standard threaded won't work. Funny, when I purchased it I told them which zerk I needed for that mower and that's what they sold me.

As such, any recommendation on sizing for a self threading zerk or perhaps tapping it myself? I'm hesitant to tap it as I don't want to damage the bearing seal.

If you had this issue, did you resolve it? I'll likely just leave as is since it sounds like a non-issue but wanted some feedback.

Thanks!