bitseeker

Silver Member

This is regarding our Kubota L5240 HST, with cab. I am hoping that someone here has had experience with the Boom-Lever that is mounted on the Loader Valve Assembly.

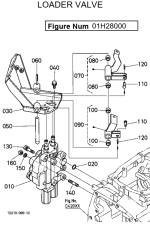

I have attached a photo of the issue and an image from the parts manual for reference.

The issue is that the lever arm controlled by the Boom Lever has broken off of the pivoting lever that moves the valve up or down. I cannot imagine what would have caused the lever to break off on this machine with just over 400 hours of moderate use and no abuse.

I can weld the lever back on to the pivoting part, BUT, I have to get the pivoting part out of the assembly to weld it properly.

As noted on the photo, the roll-pin has to be driven out of the Loader Link Bracket to allow the Link Pin to be removed, freeing the Boom Lever Assembly to be removed for prep and welding the lever back on.

I have removed the right side plastic panels from inside the cab, the access panel from the outer right-rear wheel well, and the seat and access panel under the seat. There is not sufficient access to the roll pin to drive it out either from inside or from below.

My current idea is that if I can remove the Loader Link Bracket from the Control Valve Assembly, I may then have sufficient access to the roll pin to allow it to be driven out. The parts diagram shows that there are four (4) part # 40 flange bolts attaching the Loader Link Bracket to the top of the Control Valve Assembly. I can see only two (2) of those flange bolts.

Do you know where the other two (2) flange bolts that mount the Bracket to the Valve Assembly are located?

Is there a better way?

Thanks for your assistance.

----------------------------------

UPDATE 02-12-2022 17:49:

I managed to loosen and remove the twp cable mounts and remove the headed pins with hairclip cotter pins from the top of the valves.

That done, the U-shaped valve lifters can be flipped back, revealing the other two (2) flange bolts.

The Bracket then easily came off of the Valve Assembly.

The roll-pin drove out easily with the assembly mounted in a vise.

The axle was easy to drive past the broken lever's cylindrical part.

I made up a brass drift to drive the two soft-material bushings out of the cylindrical part.

The parts are cleaned-up, beveled, and ready to weld (tomorrow when I'm fresher).

Then, reinstall the bushings and see how many sequence mistakes I can avoid on re-assembly.

I hope this does not happen to anyone else and that if it does, this writeup proves usefull.

I have attached a photo of the issue and an image from the parts manual for reference.

The issue is that the lever arm controlled by the Boom Lever has broken off of the pivoting lever that moves the valve up or down. I cannot imagine what would have caused the lever to break off on this machine with just over 400 hours of moderate use and no abuse.

I can weld the lever back on to the pivoting part, BUT, I have to get the pivoting part out of the assembly to weld it properly.

As noted on the photo, the roll-pin has to be driven out of the Loader Link Bracket to allow the Link Pin to be removed, freeing the Boom Lever Assembly to be removed for prep and welding the lever back on.

I have removed the right side plastic panels from inside the cab, the access panel from the outer right-rear wheel well, and the seat and access panel under the seat. There is not sufficient access to the roll pin to drive it out either from inside or from below.

My current idea is that if I can remove the Loader Link Bracket from the Control Valve Assembly, I may then have sufficient access to the roll pin to allow it to be driven out. The parts diagram shows that there are four (4) part # 40 flange bolts attaching the Loader Link Bracket to the top of the Control Valve Assembly. I can see only two (2) of those flange bolts.

Do you know where the other two (2) flange bolts that mount the Bracket to the Valve Assembly are located?

Is there a better way?

Thanks for your assistance.

----------------------------------

UPDATE 02-12-2022 17:49:

I managed to loosen and remove the twp cable mounts and remove the headed pins with hairclip cotter pins from the top of the valves.

That done, the U-shaped valve lifters can be flipped back, revealing the other two (2) flange bolts.

The Bracket then easily came off of the Valve Assembly.

The roll-pin drove out easily with the assembly mounted in a vise.

The axle was easy to drive past the broken lever's cylindrical part.

I made up a brass drift to drive the two soft-material bushings out of the cylindrical part.

The parts are cleaned-up, beveled, and ready to weld (tomorrow when I'm fresher).

Then, reinstall the bushings and see how many sequence mistakes I can avoid on re-assembly.

I hope this does not happen to anyone else and that if it does, this writeup proves usefull.

Attachments

Last edited: