rmorey

Platinum Member

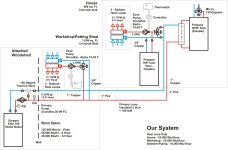

We built a home on the side of a lake. Power is 4 km away (3 miles). Solar was our only option, so we installed a 4kW system to handle our electrical requirements. We installed a wood fired 125,000 Btu boiler in the workshop to feed a 60,000 Btu/hr load. (+\-30,000 Btu/hr house, 30,000 Btu/hr workshop).

Installed 1/2" Pex Al Pex, loops are 12" apart. Each floor has 3 - 300' loops, fed from a single manifold.

Heatloss Calculations

GRUNDFOS 2699 FC pump feeds a 1" Pex main loop from boiler to house to a sidearm exchanger and back to workshop with 6 GPM/13.6' head loss. After the sidearm, secondary loop (close "T's) feeds a GRUNDFOS Alpha pump with 2 GPM/ 9.5' head loss.

Back at workshop, another secondary loop same as house. 2GPM/9.5' head loss.

Boiler manufacturer made me put a 140 degree thermic "T" valve in return line at the boiler, to keep temps above 140 degrees.

When no call for heat, or just one load calls, everything works fine. When all loads call, the cold water from floors, return to boiler and floors begin to heat. Cold water begins to cool boiler. Eventually, boiler temp drops below 140 degrees and valve closes, sending main pump output to return of boiler. Temps go up, valve opens, hot water goes to load, and cycle continues. Stove never shuts off and load never gets satisfied. Can't figure out what I've done wrong. Could use your ideas.

Installed 1/2" Pex Al Pex, loops are 12" apart. Each floor has 3 - 300' loops, fed from a single manifold.

Heatloss Calculations

GRUNDFOS 2699 FC pump feeds a 1" Pex main loop from boiler to house to a sidearm exchanger and back to workshop with 6 GPM/13.6' head loss. After the sidearm, secondary loop (close "T's) feeds a GRUNDFOS Alpha pump with 2 GPM/ 9.5' head loss.

Back at workshop, another secondary loop same as house. 2GPM/9.5' head loss.

Boiler manufacturer made me put a 140 degree thermic "T" valve in return line at the boiler, to keep temps above 140 degrees.

When no call for heat, or just one load calls, everything works fine. When all loads call, the cold water from floors, return to boiler and floors begin to heat. Cold water begins to cool boiler. Eventually, boiler temp drops below 140 degrees and valve closes, sending main pump output to return of boiler. Temps go up, valve opens, hot water goes to load, and cycle continues. Stove never shuts off and load never gets satisfied. Can't figure out what I've done wrong. Could use your ideas.