Kubota-guy1911

Silver Member

- Joined

- Oct 18, 2008

- Messages

- 152

- Location

- Glenarm, IL.

- Tractor

- Kubota L2501, Kubota BX2350, IH Cub Cadet 1450, Cub Cadet (Diesel) 1572

I didn't buy the FEL so I needed front ballast when using my carryall, boom pole, or rear blade. Not wanting to spend the $$ for the factory Kubota suitcase weights and bracket plus the shipping costs, I decided to make my own. I found some Jinma 12kG weights with free shipping on E-bay. It took 10 of them to get to the maximum recommended by Kubota. I used 3/8" X 4" and 3/8" X 2 A36 steel. I will publish the final painted product lsoon. Tomorrow I'll buy some Kubota gray paint for top coat. Here are the pics:

#2611 shows the main piece squared up and tacked into place.

#2612 shows how the weights will hang.

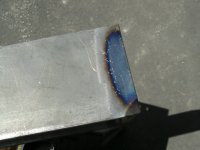

#2614 shows one of the welds close up. The little "dimples" are where I peened the weld while it was still hot to relieve internal stresses. Something my father in law taught me. We was a welder for a company in St. Louis that built highway bridges. Stoop Bros. if I remember the name of the company correctly. He died about 6 years ago and was one h@ll of a welder and I still miss him today.

#2615 shows another view of the weld partly ground smooth.

#2617 after the fillet weld was made on the underside. Plent of heat there.

#2620 drilling the weight bracket holes. Sorry about the mop behind the lamp in the background.....don't know how that got there.

#2621 primed and waiting to dry.

Final pics will have to wait a week or so...heading out of town next week and not sure exactly when I'll be back.

kj

#2611 shows the main piece squared up and tacked into place.

#2612 shows how the weights will hang.

#2614 shows one of the welds close up. The little "dimples" are where I peened the weld while it was still hot to relieve internal stresses. Something my father in law taught me. We was a welder for a company in St. Louis that built highway bridges. Stoop Bros. if I remember the name of the company correctly. He died about 6 years ago and was one h@ll of a welder and I still miss him today.

#2615 shows another view of the weld partly ground smooth.

#2617 after the fillet weld was made on the underside. Plent of heat there.

#2620 drilling the weight bracket holes. Sorry about the mop behind the lamp in the background.....don't know how that got there.

#2621 primed and waiting to dry.

Final pics will have to wait a week or so...heading out of town next week and not sure exactly when I'll be back.

kj