Thank U Oldnslo, am am trying to learn this stuff and I will look into this angle thing.

JJ,

This drawing was for trying to figure things out and not a "To Scale" deal.

As a matter of fact I planned in a 6" pipe on a slewing ring for a riser yesterday.

I have not nailed down the pressure to be used yet BUT, I am kinda hoping

I can do it in a such a manner so that in a pinch, even if a little slow, a

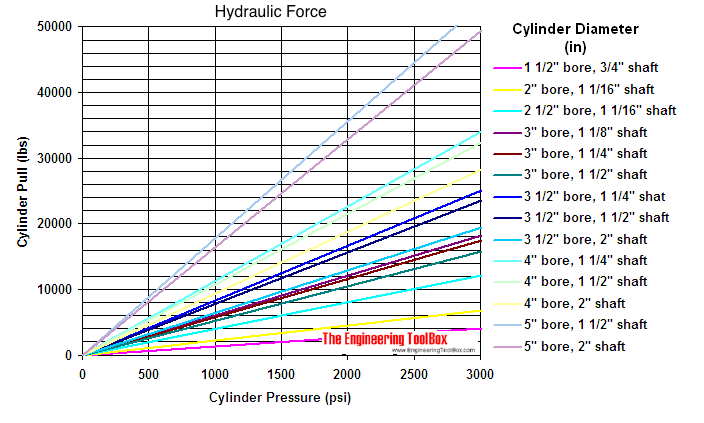

BX25 can push it (like 1800PSI MAX) or a larger 3000 PSI tractor can

push it to. I am considering all 3000PSI cylinders FWIW.

So this drawing is nothing like what I am really doing. I am really trying to figure out

how to do all these calculations so I can try to figure things out w/o having to ask for help,

and as always you J_J are there trying to help and as always I am MUCH appreciative,

THANK you.

J_J can you lead me to some online calculators or websites that explain how to do these

calculations? This device alone has 4 cylinders and I want to try to do the calcs and

figure in some overkill while I am at it but I want to "try" to learn how this stuff is done.

The boom will drop 10 degrees BELOW what is shown in this image when the cylinder

is completely retracted FWIW.