widefat

Platinum Member

- Joined

- Oct 7, 2015

- Messages

- 559

- Location

- Central Va

- Tractor

- Kubota L3200 Husq GT52XLS Husqvarna LC121P Husq 455 Rancher Stihl FS90 Stihl MS170 99 Ram 1500

Throw out some ideas - nothing is too simple; talk to me like I am 5 years old.

It is a one pipe main system.

Two zones

I believe the pressure differential is 6lbs.

Everything worked until I messed with it.

The problem -

Water is not flowing through one section of radiators.

At each end of the feed, the main pipe is hot.

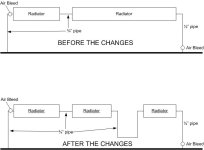

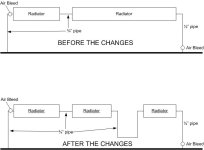

The changes - along one wall, I had one long radiator. I added a door in the middle of the wall.

To accommodate the door, I cut a section out of the radiator.

I dropped a section of pipe down underneath the doorway , through the crawlspace, and back up to the other side of the door.

I attached a drawing - note the pipe sizes.

Also note that now the water will not flow at all, from the beginning of the pic to the end, even through the unmodded radiator

So why wont water flow now?

It is a one pipe main system.

Two zones

I believe the pressure differential is 6lbs.

Everything worked until I messed with it.

The problem -

Water is not flowing through one section of radiators.

At each end of the feed, the main pipe is hot.

The changes - along one wall, I had one long radiator. I added a door in the middle of the wall.

To accommodate the door, I cut a section out of the radiator.

I dropped a section of pipe down underneath the doorway , through the crawlspace, and back up to the other side of the door.

I attached a drawing - note the pipe sizes.

Also note that now the water will not flow at all, from the beginning of the pic to the end, even through the unmodded radiator

So why wont water flow now?

Attachments

Last edited: